Will you buy your injection moulds and products in China

If you plan to import customized products, you may buy injection molds made in China at TKB, we hope you make an informed decision before purchasing molds and products. That’s why we offer this injection mold buying guide to help you decide.

Injection molds are critical to your new project and can take months or even years to complete. Therefore, you should make sure to choose the right solution to take your ideas and projects from concept to reality.

1. before the start

When do you need custom molds?

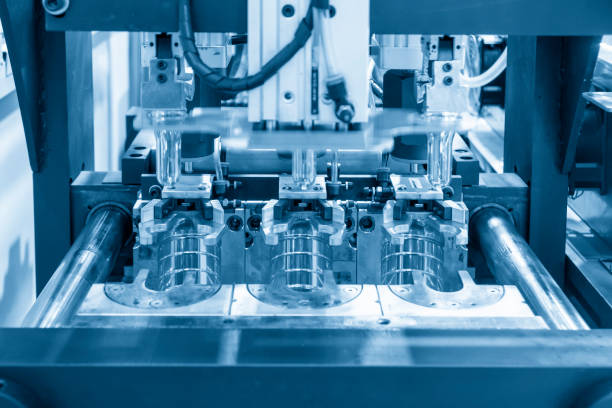

A mold is a hollow container used to shape molten or hot liquid as it cools and hardens

Water in a round cup is a cylinder, while water in a square cup is a cuboid. The function of the mold is similar to this cup

If you want to custom design a product or make changes to an existing product, you will need a mold. Different product materials and structures require different types of molds, and injection molds are suitable for most plastic products.

2. Product Analysis and Quotation

How to prepare for an RFQ

The preparation depends on your requirements for the product, the easiest way is to send us yours: product design, order quantity, product working condition, etc.

We will then take care of all other work including material selection, design analysis, mold design and fabrication, product mass production, and final delivery. If necessary, we can even ship the goods from China to your place.

If you are an engineer or work with an engineer, detailed requirements for mold material, brand and type, and mold construction requirements will provide you with a corresponding quotation. Your mold specifications and information will be completed by our professional engineering team.

How long does it take to quote

Quotes usually take 2 days or less. A very complex project may require more time.

Before quoting, your product design will undergo a preliminary inspection taking into account mold and product manufacturability. If there is anything that needs to be modified, please suggest it.

How much should I pay for the mold?

Mold price depends on mold material, part size, complexity, etc. For simple prototype injection molds.

However, for larger or more complex products, or for products with higher product tolerances. Better molds have longer mold life and injection times.

Several factors to consider in the cost of injection molds

mold design

How long does mold design take, mold design usually takes a week? Complex products may require more time. The mold design will be provided to you for approval before we start manufacturing.

What is DFM

Design for Manufacturing (DFM) analysis is a core issue before we start making molds for you. This is to let you know what we are analyzing and how we will make the mold. It will be sent to you for approval and revisions based on your comments until you are satisfied. Please buy our products now.

-

Creating a Plastic Stool Mold manufacture: A Step-by-Step Guide to Manufacturing

2023-8-5

Plastic stools are commonly used in various settings, such as homes, offices, and outdoor spaces. These versatile and li...

View details -

How Injection Molding Revolutionized Manufacturing

2023-4-14

Injection molding is a manufacturing process that has revolutionized the way products are made. It is a process that inv...

View details -

Creating High-Quality Industrial Molding Parts

2023-4-21

Industrial molding is the process of creating plastic parts using molds. It is a crucial process in various industries, ...

View details -

China Home Appliance Molding Parts

2023-4-27

Home appliance molding parts are crucial components that are used in various household appliances. These parts are desig...

View details -

China Injection Mold Manufacturing: The Key to Efficient and High-Quality Production

2023-5-25

Injection mold manufacturing is a crucial process in the production of plastic and metal parts. It is a method used to c...

View details -

Precision Aerospace Molding: Producing High-Quality Parts for Flight and Beyond

2023-5-19

Precision Aerospace Molding is a trusted provider of high-quality, custom material solutions for aviation and aerospace....

View details