Creating High-Quality Electronics Mold for Enhanced Product Performance

Over the years, the demand for high-quality electronic products has significantly increased as technological advancements continue to transform various industries. The success of electronic products largely depends on the quality of the mold used during the manufacturing process. A high-quality mold can significantly enhance the performance of electronic products, while a low-quality mold can result in substandard products, which can lead to customer dissatisfaction and loss of revenue. In this article, we will explore the importance of creating high-quality electronics molds and the steps involved in the process.

Importance of High-Quality Electronics Mold

The quality of the mold used is crucial in determining the performance of electronic products. A high-quality mold ensures that the product is produced consistently and meets the required standards. This is particularly important in the manufacture of electronic products, where precision and accuracy are critical for optimal performance. A high-quality mold also ensures that the product is durable, reliable, and safe for users. It eliminates the risk of product failure, which can be costly in terms of customer satisfaction, recalls, and potential legal liabilities.

Another advantage of using high-quality electronics molds is that they can significantly reduce the production time and costs. A high-quality mold can produce products faster and with fewer defects, reducing the need for rework and waste. This translates to increased efficiency, reduced production costs, and increased profitability.

Steps in Creating High-Quality Electronics Mold

Creating high-quality electronics molds requires a systematic and rigorous process that involves several steps. The following are the key steps involved in the process:

1. Designing the Mold

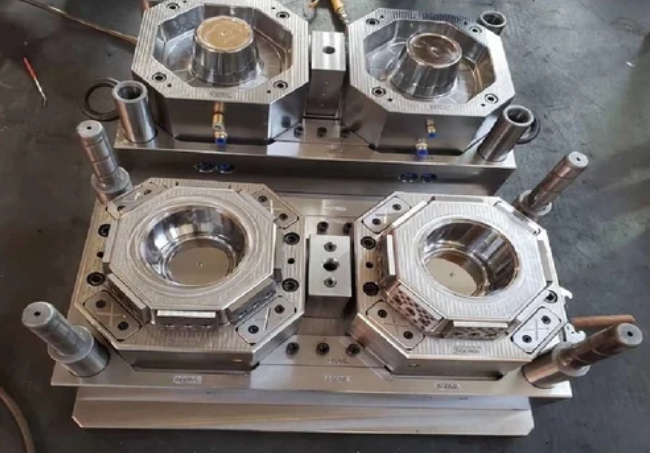

The first step in creating a high-quality electronics mold is designing the mold. The mold design must be precise and accurate to ensure that the final product meets the required specifications. This involves creating a detailed design that includes all the necessary components, such as the cavities, gates, and cooling systems.

2. Prototyping

Once the mold design is complete, the next step is to create a prototype mold. The prototype mold is used to test the design and ensure that the mold can produce the required product with the desired quality. The prototype mold is also used to make any necessary adjustments to the design before proceeding to the next stage.

3. Manufacturing the Mold

After the prototype stage, the next step is to manufacture the mold. The manufacturing process involves several stages, including cutting, drilling, milling, and polishing. The mold must be made with high-precision tools and equipment to ensure that it meets the required specifications.

4. Testing and Inspection

Once the mold is manufactured, it must be tested and inspected to ensure that it meets the required quality standards. This involves performing various tests, such as dimensional accuracy, surface finish, and material hardness tests. The mold must also be inspected visually to ensure that all the components are properly aligned, and there are no defects or damages.

5. Maintenance and Repair

Finally, to ensure that the mold continues to produce high-quality products, regular maintenance and repair are required. This involves cleaning, lubricating, and replacing worn-out parts to ensure that the mold remains in optimal condition.

Conclusion

Creating high-quality electronics molds is critical in ensuring that electronic products meet the required standards and perform optimally. The mold design must be precise and accurate, and the manufacturing process must be rigorous to produce a mold that is durable, reliable, and safe for users. The steps involved in creating high-quality electronics molds include designing, prototyping, manufacturing, testing and inspection, and maintenance and repair. By following these steps, manufacturers can create high-quality molds that enhance the performance of electronic products and increase profitability.

ก่อนหน้า:Manufacturing Essential Components: Industrial Molding Parts

ต่อไป: Exploring the Benefits and Process of Plastic Injection Molding

-

Manufacturing Custom Industrial Molding Parts

2023-6-24

Custom industrial molding parts are critical components in the manufacturing industry. They play a crucial role in creat...

ดูรายละเอียด -

Crate Mould: Designing and Manufacturing High-Quality Plastic Crates

2023-6-13

In today's world, plastic crates have become an essential part of the logistics industry. They are used to transport var...

ดูรายละเอียด -

Creating Efficient Plastic Chair Injection Molds for Optimal Production

2023-6-21

Plastic chairs are a common sight in homes, offices, and public spaces. They are lightweight, durable, and affordable, w...

ดูรายละเอียด -

Crafting a Perfect Plastic Chair Mould: The Art of Designing Durable and Stylish Seating Solutions

2023-12-6

Plastic chairs have become ubiquitous in our modern society. They can be found in homes, offices, restaurants, and outdo...

ดูรายละเอียด -

ชิ้นส่วนแม่พิมพ์เครื่องใช้ในบ้าน

2023-4-22

Home appliances have become a crucial part of our daily lives. They make our lives easier, simpler, and more comfortable...

ดูรายละเอียด -

What is the process of plastic mold making?

2024-11-16

Plastic mold making is a complex and delicate process that involves multiple steps and multiple technologies. The core o...

ดูรายละเอียด