ஊசி மோல்டு: வெகுஜன உற்பத்திக்கான செலவு குறைந்த தீர்வு

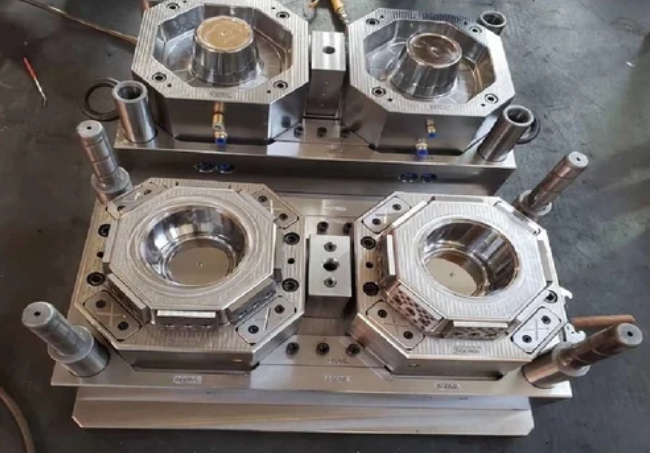

Injection molding is a manufacturing process used to produce large quantities of identical parts. It involves melting plastic pellets and injecting them into a mold to form the desired shape. The molded parts can be used for a wide variety of products and applications, ranging from automotive parts to kitchen utensils. Injection molding is a cost-effective solution for mass production because it allows for high volume production with consistent quality.

One of the key advantages of injection molding is its ability to produce large volumes of parts quickly and efficiently. With the use of automated machinery and high-speed production techniques, it is possible to produce thousands of parts per hour. This makes injection molding an ideal solution for companies that need to produce large quantities of parts for their products.

Another advantage of injection molding is its ability to produce parts with consistent quality. The use of automated machinery and precise molds ensures that each part is identical to the next. This is important for products that require a high degree of precision, such as medical devices or electronic components.

Injection molding also allows for a wide range of materials to be used in production. Plastics such as polypropylene, nylon, and polycarbonate can be easily molded using this process. Other materials such as metals and ceramics can also be molded, making injection molding a versatile solution for many different industries.

In addition to its cost-effectiveness and versatility, injection molding offers other benefits as well. For example, it allows for complex part geometries to be produced with ease. The molds used in injection molding can be designed to produce parts with intricate shapes and details, which may not be possible with other manufacturing processes.

Injection molding also produces minimal waste, making it a sustainable and environmentally friendly manufacturing process. The scraps and excess materials generated during production can be recycled and reused, reducing the amount of waste that is sent to landfills.

Overall, injection molding is a cost-effective and efficient solution for mass production. Its ability to produce large volumes of parts quickly and consistently makes it a popular choice for many industries. As technology continues to advance, we can expect to see even more innovations in injection molding that will further improve its efficiency and versatility.

முந்தைய:பெரிய பிளாஸ்டிக் மோல்டுகளை உருவாக்குதல்: ஒரு விரிவான வழிகாட்டி

அடுத்தது: Injection Molding: Creating Precise and Efficient Plastic Parts

-

Designing a High-Quality Plastic Bucket Mould with Precision and Efficiency

2023-7-5

Plastic buckets have become an integral part of our daily lives, serving various purposes in households, industries, and...

விபரங்களை பார் -

Designing the Perfect Plastic Chair Mould: A Masterpiece of Innovation in English

2023-6-30

Plastic chairs have become an integral part of our daily lives. Whether it's at home, in the office, or even in public s...

விபரங்களை பார் -

Creating a High-Quality Plastic Pallet Mould: An Expert Guide

2023-8-25

Introduction Plastic pallets have gained immense popularity in industries around the world due to their durability, cost...

விபரங்களை பார் -

Plastic Injection Molding Machine: Streamlining Manufacturing Processes

2023-5-7

Plastic injection molding machines are a vital component of modern manufacturing processes. This type of machine is used...

விபரங்களை பார் -

What is the process of plastic mold making?

2024-11-16

Plastic mold making is a complex and delicate process that involves multiple steps and multiple technologies. The core o...

விபரங்களை பார் -

Plastic Injection Molding wholesale: Streamlining Manufacturing Processes

2023-5-11

Plastic injection molding is a manufacturing process that has become increasingly popular due to its ability to produce ...

விபரங்களை பார்