About mold for plastic injection

Mold can be a big issue when it comes to plastic injection. In order to produce high-quality parts, it is important to understand the basics of mold and how it can affect the process.

What is mold for plastic injection?

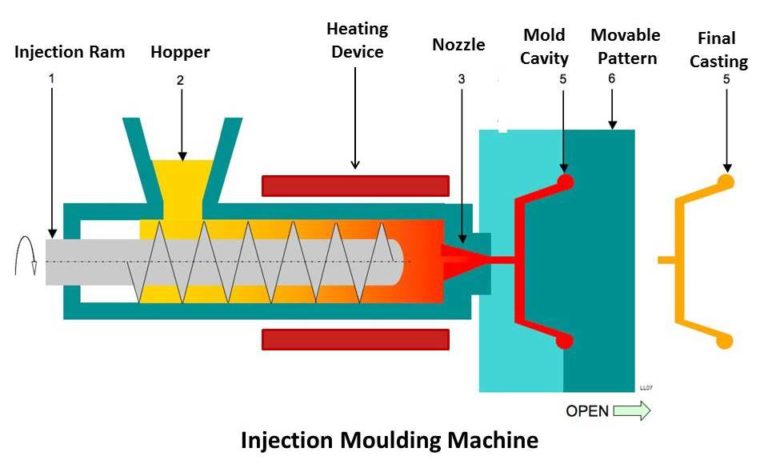

Mold is the most important tool for plastic injection. It is used to form the plastic parts and components. The type and design of the mold will determine the quality of the molded parts. The mold must be able to withstand the high temperatures and pressures of the injection process. It must also be able to produce the desired shape and size of the parts.

What factors affect the choice of mold type?

There are many factors that can affect the choice of mold type. The most important factors are the type of plastic, the shape of the part, and the required accuracy.

The type of plastic can impact the choice of mold type. For example, thermoset plastics can’t be melted and reshaped, so they require a different mold type than thermoplastic plastics.

The shape of the part can also affect the choice of mold type. Parts with complex shapes or features that need to be reproduced with high accuracy can require a more expensive mold type.

The required accuracy can also impact the choice of mold type. Some mold types are more accurate than others, so it’s important to choose the right type for the job.

How is the quality of the mold ensured?

In order to ensure the quality of the mold, a number of factors must be considered. The first is the material that is to be used to create the mold. The material must be strong and durable so that it can withstand the heat and pressure of the casting process. The material must also be able to produce a accurate mold. The second factor is the design of the mold. The design must be carefully planned so that the mold can be easily produced. The third factor is the manufacturing process. The process must be carefully controlled to ensure that the mold is produced accurately.