About Insert Molding: How Large Plastic Mold Makers Are Meeting Industry Demand

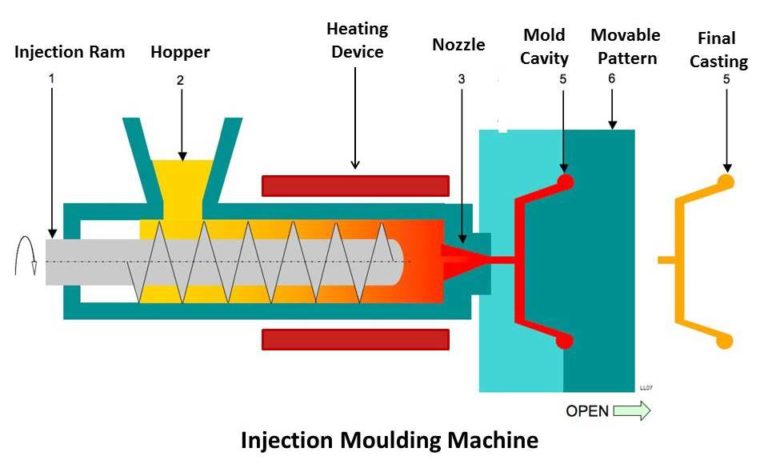

Insert molding is becoming an increasingly popular technique for creating plastic parts, and large plastic mold makers are at the forefront of meeting the demand for this process. In insert molding, a pre-formed insert is placed into a mold, and molten plastic is then injected around it to create a finished part.

One of the main advantages of insert molding is that it can be used to create complex parts with multiple components, which can save time and reduce assembly costs. Additionally, insert molding allows for greater precision and tighter tolerances, which is especially important in industries such as automotive and medical device manufacturing.

Large plastic mold makers are meeting industry demand for insert molding by investing in state-of-the-art machinery and employing highly skilled technicians. They are also working closely with customers to understand their specific needs and requirements, and developing customized solutions that meet those needs.

As demand for insert molding continues to grow, large plastic mold makers are pushing the limits of innovation to find new and creative ways to use the process. They are experimenting with new materials, developing new techniques, and exploring new applications to create products that are stronger, more durable, and more efficient than ever before.

Overall, insert molding is a valuable tool in the large plastic mold maker’s toolbox, and these companies are using it to meet industry demand and drive innovation in the manufacturing industry.