About Big Injection Molds in China: Meeting the Demands of a Rapidly Growing Consumer Market

China’s big injection mold industry is a key player in meeting the demands of the rapidly growing consumer market in China and around the world. As consumer preferences continue to evolve and diversify, manufacturers are seeking new ways to produce high-quality products at a lower cost and with faster turnaround times.

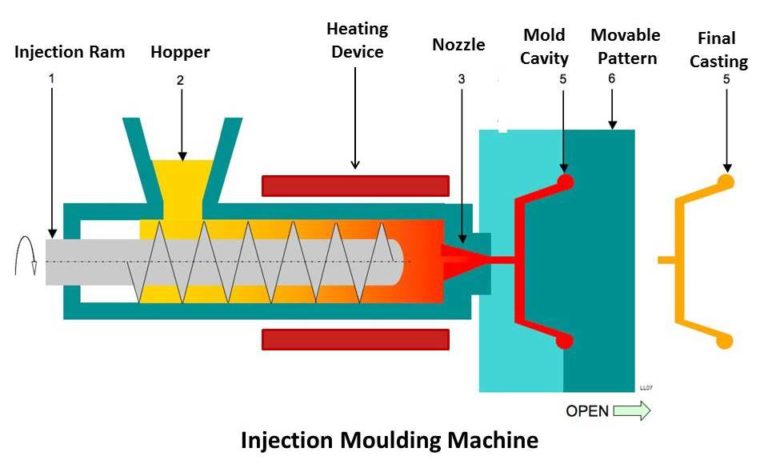

One way that manufacturers are meeting these demands is by investing in large, high-speed injection molding machines. These machines are capable of producing large volumes of high-quality parts quickly and efficiently, which is essential for meeting the needs of the consumer market.

Another key factor driving the growth of the big injection mold industry in China is the country’s highly skilled workforce. China has a large pool of highly trained engineers and technicians who are able to design and manufacture complex molds with a high degree of precision.

In addition to these advantages, China’s big injection mold industry is also benefiting from the country’s growing middle class and their increasing demand for high-quality consumer products. This has created a strong market for injection molded products such as automotive components, electronic devices, and household goods.

Overall, the big injection mold industry in China is poised for continued growth as manufacturers continue to invest in technology, skilled labor, and advanced production techniques to meet the demands of the rapidly growing consumer market. By staying ahead of the curve and adapting to changing market conditions, China’s big injection mold industry is helping to shape the future of global manufacturing.