Wholesale Injection Molding Parts Online: A Key Component for Manufacturing Success

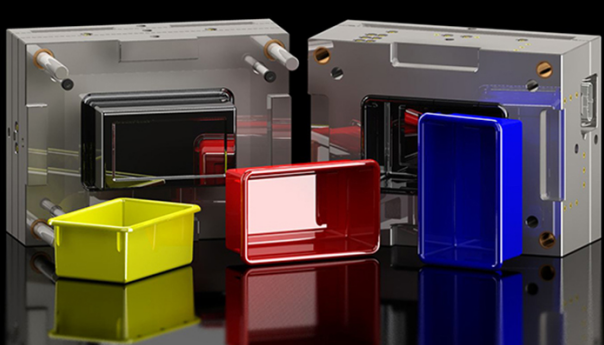

Injection molding is a widely used manufacturing process that involves melting plastic pellets and injecting the molten material into a mold cavity. The process is used to produce a wide range of plastic parts and components, from small and intricate pieces to large and complex products. Injection molding parts are a key component for manufacturing success, as they are used in many industries and applications.

Injection molding parts are used in various industries, including automotive, aerospace, electronics, medical, and consumer goods. These parts are used in the production of products such as automotive components, electronic devices, medical equipment, and toys. Injection molding parts are also used in the production of packaging materials, such as bottles and containers.

Injection molding parts are essential for manufacturing success because they are produced with high accuracy and consistency. The injection molding process allows for precise control of the material flow and temperature, ensuring that each part is produced to the same high standard. This consistency is important for products that require precise dimensions and tolerances, such as medical equipment and electronic devices.

Injection molding parts are also cost-effective. The process allows for the production of large quantities of parts at a lower cost than other manufacturing methods. This is because the injection molding process is highly automated, reducing the need for labor and increasing efficiency. Additionally, the use of plastic materials in injection molding is cost-effective compared to other materials such as metal.

Injection molding parts are also durable and long-lasting. The plastic materials used in injection molding are strong and resistant to wear and tear, making them ideal for use in products that require long-term durability, such as automotive components and industrial machinery. The durability of injection molding parts also makes them a sustainable choice, as they have a longer lifespan than many other materials.

In conclusion, injection molding parts are a key component for manufacturing success. They are used in various industries and applications, providing high accuracy and consistency, cost-effectiveness, durability, and sustainability. Injection molding is a highly versatile process that allows for the production of a wide range of plastic parts and components, making it an essential part of modern manufacturing.

ທີ່ຜ່ານມາ:Medical Molding Parts manufacture: Precision and Quality in Medical Device Manufacturing

ຕໍ່ໄປ: The Advantages of Using a Plastic Injection Molding Machine

-

ຄວາມຕ້ອງການຂອງແມ່ພິມສີດພາດສະຕິກທີ່ມີຄວາມເງົາສູງແລະແມ່ພິມ

2021-8-11

ໃນປັດຈຸບັນ, ສ່ວນໃຫຍ່ຂອງຮູບລັກສະນະຂອງເຄື່ອງໃຊ້ໃນຄົວເຮືອນແມ່ນຜ່ານການສີດແມ່ພິມແບບດັ້ງເດີມ, ແລະມັນງ່າຍ ...

ເບິ່ງລາຍລະອຽດ -

Injection Mold Components: Key Parts for High-Quality Manufacturing

2023-6-24

Injection molding is a widely used manufacturing process that produces a large number of parts for various industries, i...

ເບິ່ງລາຍລະອຽດ -

How are precision moulds made?

2024-12-3

In the vast field of manufacturing, precision moulds play a vital role. Not only are they key tools in the production of...

ເບິ່ງລາຍລະອຽດ -

Injection Molding Parts: The Key Components for High-Quality Manufacturing

2023-4-24

Injection molding is a widely used manufacturing process that involves injecting molten material into a mold to create a...

ເບິ່ງລາຍລະອຽດ -

Eliminating Car Door Mold: Effective Measures to Keep Your Vehicle Fresh and Clean

2023-8-27

Introduction Maintaining a clean and fresh-smelling car is essential for both comfort and health. One common problem tha...

ເບິ່ງລາຍລະອຽດ -

ແມ່ພິມພາດສະຕິກຂະຫນາດໃຫຍ່ທຸກຢ່າງທີ່ເຈົ້າຕ້ອງການຮູ້

2023-2-16

ແມ່ພິມພາດສະຕິກຂະຫນາດໃຫຍ່ແມ່ນສ່ວນຫນຶ່ງທີ່ສໍາຄັນຂອງຂະບວນການຜະລິດຈໍານວນຫຼາຍ. ຖ້າທ່ານບໍ່ຄຸ້ນເຄີຍກັບພວກມັນ, ຫຼືຕ້ອງການເພີ່ມເຕີມ ...

ເບິ່ງລາຍລະອຽດ