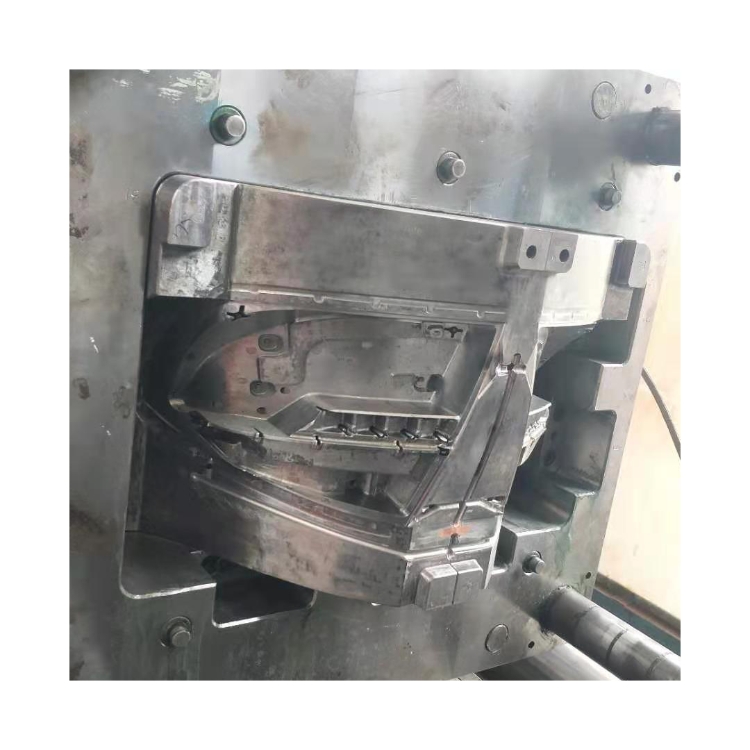

Creating Molding Parts for Home Appliances

Molding is an important process in manufacturing home appliances. This process involves creating a mold or pattern that is used to create a product. In this case, the product is a part or component of a home appliance. Molding can be done using a variety of materials, including plastic, metal, and ceramics. The process of creating molding parts for home appliances requires a lot of skill and expertise. In this article, we will discuss the process of creating molding parts for home appliances and the different materials used in this process.

Materials Used in Creating Molding Parts for Home Appliances

There are several materials used in creating molding parts for home appliances. The most common materials used are thermoplastics, thermosetting plastics, and metal. Thermoplastics are a type of plastic that can be melted and re-molded. They are commonly used in the manufacturing of home appliances because they are easy to work with and can be molded into complex shapes. Thermosetting plastics, on the other hand, are a type of plastic that cannot be re-molded or melted. They are used in the manufacturing of parts that require high strength and durability.

Metal is also used in creating molding parts for home appliances. It is commonly used in the manufacturing of parts that require high strength and durability. The most commonly used metals in molding are aluminum, magnesium, and zinc.

Process of Creating Molding Parts for Home Appliances

The process of creating molding parts for home appliances involves several steps. The first step is to create a mold or pattern. This mold or pattern is used to create the product. The mold is created using a variety of materials, including wood, metal, or plastic.

Once the mold or pattern is created, the material is melted and poured into the mold. This material is then allowed to cool and harden. Once the material has hardened, the mold is removed, and the product is ready for use.

The process of creating molding parts for home appliances requires a lot of skill and expertise. It is important to have a good understanding of the materials used in this process and the different techniques involved in creating molding parts.

In conclusion, creating molding parts for home appliances is an important process in manufacturing. The process requires a lot of skill and expertise, and the materials used in this process are critical to the success of the final product. The most commonly used materials in creating molding parts for home appliances are thermoplastics, thermosetting plastics, and metal. With the right expertise and materials, creating molding parts for home appliances can be a successful and profitable business.

ທີ່ຜ່ານມາ:ເຄື່ອງໃຊ້ໃນເຮືອນ Molding Parts

-

Precision Injection Molding for High-Quality Plastic Products

2023-5-21

Precision injection molding is a manufacturing process used to produce high-quality plastic products with exceptional ac...

ເບິ່ງລາຍລະອຽດ -

The Cost of Injection Molding: Understanding the Factors That Affect Pricing

2023-6-27

The process of injection molding is one of the most common methods used for manufacturing plastic products, including ev...

ເບິ່ງລາຍລະອຽດ -

Aerospace Molding Parts: Enhancing Performance in Aerospace Technology

2023-6-21

Aerospace technology has been advancing rapidly over the past few decades. With the advent of new technologies and the a...

ເບິ່ງລາຍລະອຽດ -

ການຜະລິດເຄື່ອງມືມີເທກໂນໂລຍີກ້າວຫນ້າເພື່ອເພີ່ມປະສິດທິພາບການຜະລິດແລະຄຸນນະພາບ

2022-10-6

ໃນສະພາບແວດລ້ອມການຜະລິດ, ການມີເຄື່ອງມືທີ່ເຫມາະສົມແມ່ນສໍາຄັນໃນການຜະລິດຜະລິດຕະພັນທີ່ມີຄຸນນະພາບທີ່ແທ້ຈິງ, ເຄື່ອງມືການນໍາໃຊ້ ...

ເບິ່ງລາຍລະອຽດ -

Analysis of the manufacturing process and quality control points of high-precision automotive molds

2024-12-18

The manufacturing process of high-precision automotive molds is complex and delicate, and the quality control points are...

ເບິ່ງລາຍລະອຽດ -

Designing the Perfect Plastic Bottle Crate Mold for Efficient Packaging Solutions

2023-9-25

Introduction Efficient packaging solutions are crucial for businesses to streamline their operations and maximize their ...

ເບິ່ງລາຍລະອຽດ