About plastic injection molding manufacturer

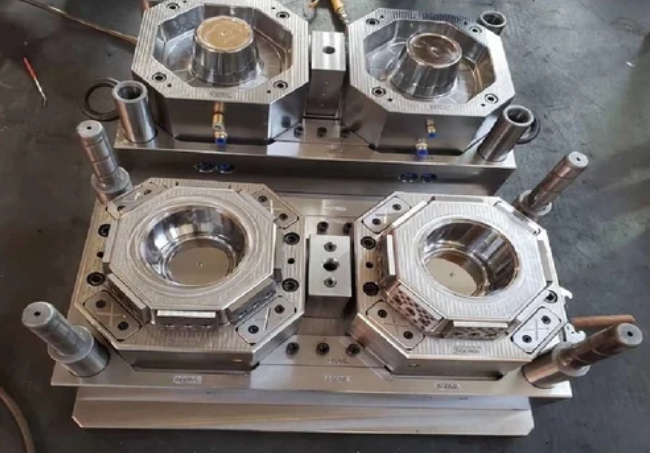

The plastic injection moulding process produces large numbers of parts of high quality with great accuracy, very quickly. It consists of two main parts, an injection unit and a clamping unit. Injection mold manufacturing is typically used when the same part is being created thousands or even millions of times in succession and a plastic mold maker is needed to handle the production of these. The process of plastic injection molding is fast, meant to produce large quantities of the same plastic product in a short time span. Nevertheless, many people use the term to name the complete product manufacturing. Injection molding is so popular, because of the dramatically low cost per unit when manufacturing high volumes. A wide variety of products are manufactured using injection molding, which vary greatly in their size, complexity, and application. And then, the mould cools down the injected molten material.

Injection Molding is a manufacturing process for producing parts in large volumes. It is most typically used in mass-production processes where the same part is being created thousands or even millions of times in succession.

The principal advantage of injection molding is the ability to scale production en masse. Once the initial costs have been paid the price per unit during injection molded manufacturing is extremely low. The price also tends to drop drastically as more parts are produced.

Injection molding produces low scrap rates relative to traditional manufacturing processes like CNC machining which cut away substantial percentages of an original plastic block or sheet. This however can be a negative relative to additive manufacturing processes like 3D printing that have even lower scrap rates.

Injection molding is a manufacturing process for producing parts by injecting molten material into a mould, or mold. The plastic injection moulding process produces large numbers of parts of high quality with great accuracy, very quickly. Bill details the key engineering principles underlying plastic injection molding. Injection molding is so popular, because of the dramatically low cost per unit when manufacturing high volumes. A special machine injects liquid plastic material into a customized mold that shapes the final strictly, this is the complete injection molding process.