Medical injection molds: precision tools for shaping medical health

In today’s rapidly changing medical technology, medical injection molds, as the core tools in medical device manufacturing, are providing solid support for the innovative development of the medical industry with their high precision, high quality and high efficiency. Medical injection molds not only meet the strict requirements of medical devices for precision and reliability, but also play an irreplaceable role in improving production efficiency, ensuring product quality and promoting medical technology progress.

一、Basic structure and composition of medical injection molds

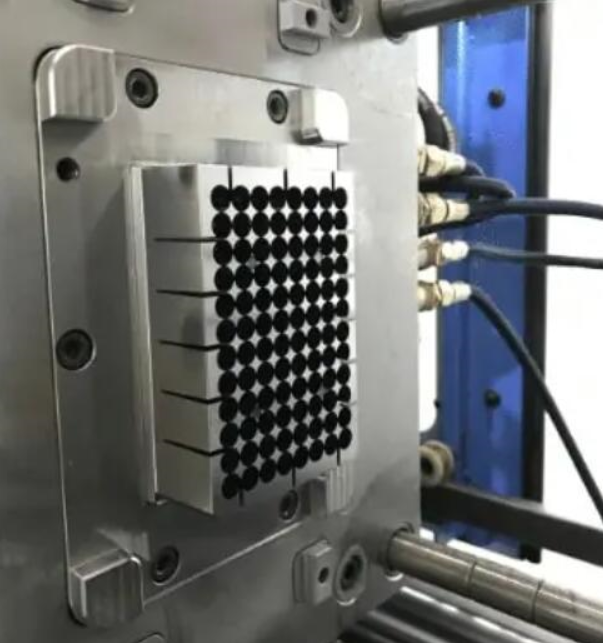

Medical injection molds are mainly composed of two core parts: concave molds and convex molds. Concave molds usually include key components such as concave mold combination base plate, concave mold assembly and concave mold combination pallet, while convex molds include convex mold combination base plate, convex mold assembly, convex mold combination pallet and cavity truncation assembly. Through precise design and coordinated changes, these components enable the mold to adapt to the production of plastic products of different shapes and sizes, thereby meeting the needs of the medical field for diversified medical devices.

二、 Application and advantages of medical injection molds

1. Efficient production: Medical injection molds can quickly and accurately produce medical supplies of various shapes and specifications, such as syringes, infusion sets, blood collection devices, etc. By introducing automation and intelligent technology, molds can achieve efficient and large-scale production, significantly improve production efficiency, reduce production costs, and provide a strong guarantee for the adequate supply of medical resources.

2. Quality assurance: The quality and performance of the mold directly affect the quality of the finished product. Medical injection molds use advanced manufacturing processes and materials to ensure that the medical devices produced have excellent quality and safety, meet the strict clinical requirements for medical supplies, and provide patients with safer and more effective treatment methods.

3. Flexible and changeable: The convex and concave molds and auxiliary molding systems of medical injection molds can be coordinated and changed, so that the mold can process a series of plastic parts of different shapes and sizes. This high degree of flexibility enables the mold to adapt to the ever-changing needs of the medical field and provides more possibilities for medical innovation.

三、 Characteristics and requirements of medical injection molds

1. Simple and beautiful appearance design: Modern medical product design focuses on simplicity and beauty. When designing medical injection molds, the simplicity of product shape, color, material and process should be pursued to meet the aesthetic needs of medical products.

2. High precision: Medical product injection mold designers need to accurately grasp the dimensional accuracy of plastic parts and molds to ensure product quality and interchangeability. High precision is an important feature of medical injection molds and the key to ensuring the stable performance of medical devices.

3. Easy operation and maintenance: Mold design should take into account the different cognitive abilities of users, and the operation should be easy to understand and remember. At the same time, the mold should have good durability and easy maintenance to reduce production costs and improve production efficiency.

As a key tool in the manufacture of medical devices, medical injection molds provide strong support for the innovative development of the medical industry with their high precision, high quality and high efficiency. By continuously optimizing the design and manufacturing process, we can expect more efficient, more accurate and safer medical injection molds to bring more innovative results to the medical industry and contribute more to the cause of human health.

前:Analysis of the manufacturing process and quality control points of high-precision automotive molds

次: Injection mold making: Precision processes shaping the future of industry

-

China Creating an Injection Chair Mould: Expertise in English

2023-8-17

Designing and manufacturing an injection chair mould requires expertise in various aspects of engineering and craftsmans...

詳細を見る -

Injection Molding | Manufacturing for Repeatable Quality

2023-5-18

Injection molding is one of the widely accepted methods for manufacturing plastic components that actualizes features ra...

詳細を見る -

Unleashing the Power of Insert Mold: Revolutionizing Manufacturing with English

2023-8-8

Introduction In today's fast-paced world, innovation and efficiency are essential for businesses to stay competitive. Am...

詳細を見る -

Precision Aerospace Molding Parts for Reliable Performance

2023-5-18

Precision aerospace molding parts play a vital role in the aerospace industry by providing equipment that delivers relia...

詳細を見る -

Injection Molding for Automotive Parts

2023-6-3

Injection molding is a widely used manufacturing process in the automotive industry for the production of high-quality a...

詳細を見る -

Automotive Mold: A Key Component in Vehicle Manufacturing

2023-4-16

Automotive mold is a critical component in vehicle manufacturing. It is used to create the various parts of a vehicle, r...

詳細を見る