Designing an Efficient Plastic Pallet Mould for Optimum Performance

Plastic pallets have become increasingly popular in recent years due to their numerous advantages over traditional wooden pallets. They are lightweight, durable, and easy to clean, making them ideal for use in various industries such as food and beverage, pharmaceuticals, and logistics. However, the key to producing high-quality plastic pallets lies in the design of the mould used in the manufacturing process. In this article, we will explore the various factors that go into designing an efficient plastic pallet mould for optimum performance.

1. Material Selection

The first step in designing a plastic pallet mould is to select the appropriate material. The most commonly used material for plastic pallets is high-density polyethylene (HDPE). HDPE is a thermoplastic material that is known for its high strength, rigidity, and impact resistance. It is also resistant to chemicals and UV radiation, making it ideal for outdoor use. Other materials such as polypropylene (PP) and polycarbonate (PC) can also be used depending on the specific requirements of the pallet.

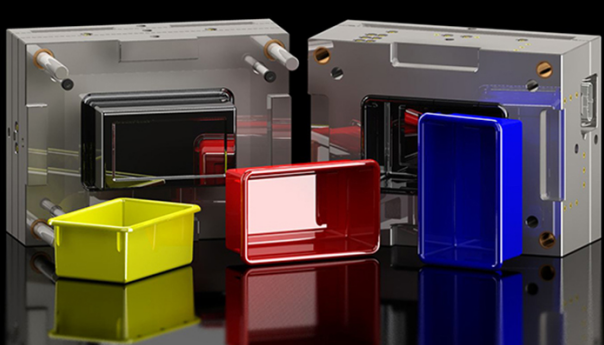

2. Mould Design

The next step is to design the mould itself. The mould must be designed to produce consistent, high-quality pallets with minimal waste. This requires careful consideration of factors such as parting line location, gate location, and cooling system design.

Parting line location refers to the line where the two halves of the mould meet. This can have a significant impact on the quality of the finished product. A poorly designed parting line can result in flash, which is excess plastic that protrudes from the parting line and must be trimmed off. This can increase waste and production time. A well-designed parting line will minimize flash and produce a clean, uniform finish.

Gate location is another important factor to consider. The gate is the point where the molten plastic enters the mould. The location of the gate can affect the flow of plastic through the mould, which can impact the quality of the finished product. A gate that is too small can result in a weak spot in the pallet, while a gate that is too large can result in excessive flash.

The cooling system design is also critical to producing high-quality plastic pallets. The cooling system must be designed to ensure that the plastic cools evenly and at the right rate. If the cooling is uneven, it can result in warping or distortion of the pallet. If the cooling is too slow, it can increase production time and reduce efficiency.

3. Manufacturing Process

Once the mould is designed, the manufacturing process can begin. The first step is to create a prototype of the mould to ensure that it produces the desired results. This prototype can be used to make any necessary adjustments before production begins.

During production, it is important to monitor the process carefully to ensure that the mould is functioning properly. This includes monitoring the temperature, pressure, and flow of the molten plastic. Any deviations from the desired parameters should be addressed immediately to ensure that the final product meets the required specifications.

4. Maintenance

Finally, it is important to maintain the mould properly to ensure its longevity and continued efficiency. This includes regular cleaning and inspection to ensure that there is no damage or wear. Any damage or wear should be addressed immediately to prevent further damage and reduce the risk of producing defective products.

In conclusion, designing an efficient plastic pallet mould for optimum performance requires careful attention to material selection, mould design, manufacturing process, and maintenance. A well-designed mould will produce consistent, high-quality pallets with minimal waste, resulting in increased efficiency and cost savings. By following these guidelines, manufacturers can produce plastic pallets that meet the specific requirements of their industry and provide long-lasting value.

前:Designing a Plastic Bottle Crate Mould: The Ultimate Guide

次: The Cost of Injection Molding: Understanding the Factors That Affect Pricing

-

Mold Design facture: Creating Perfect Molds for Your Manufacturing Needs

2023-6-2

Mold design is a crucial part of manufacturing. Creating a perfect mold requires a deep understanding of the manufacturi...

詳細を見る -

Medical Molding Parts: High-Quality Components for the Healthcare Industry

2023-5-3

Medical molding parts are essential components used in the healthcare industry to create high-quality medical devices an...

詳細を見る -

China Injection Molding: Plastic Injection Molding Machine

2023-5-9

Introduction Plastic injection molding is a manufacturing process that involves the creation of three-dimensional solid ...

詳細を見る -

How are precision moulds made?

2024-12-3

In the vast field of manufacturing, precision moulds play a vital role. Not only are they key tools in the production of...

詳細を見る -

Designing a High-Quality Plastic Bucket Mould with Precision and Efficiency

2023-7-5

Plastic buckets have become an integral part of our daily lives, serving various purposes in households, industries, and...

詳細を見る -

Injection Mold: The Process and Advantages

2023-4-16

Injection molding is a commonly used manufacturing process that involves the creation of complex parts and products by i...

詳細を見る