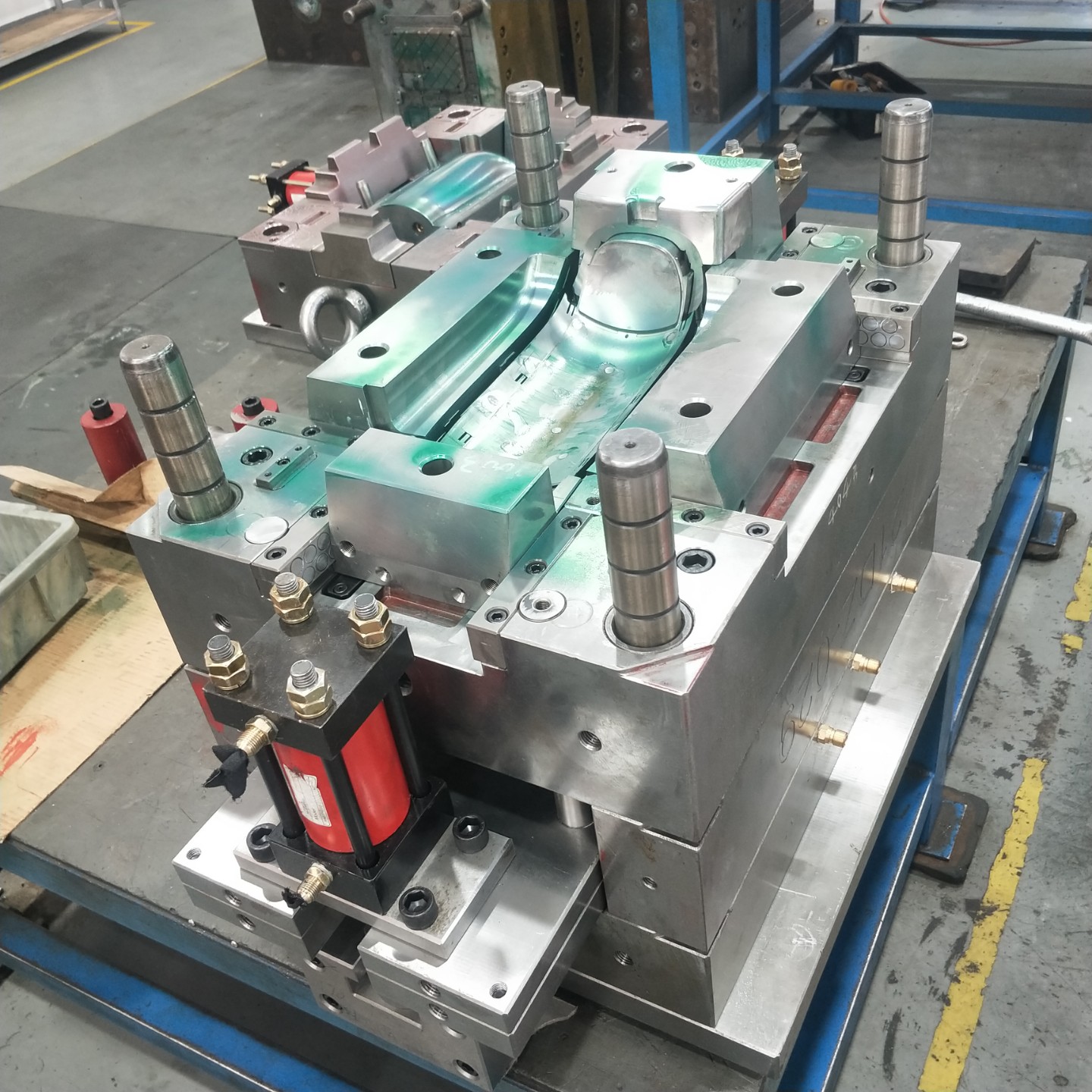

Importanza della manutenzione degli stampi ad iniezione

Compared with other molds, the structure of injection mold is more complex and precise, and the requirements for the operation and maintenance of products are higher. Therefore, in the whole production process, the use of positive solutions and careful maintenance, maintenance to maintain the nromal production of enterprises, improve enterprise benefits, has a very important significance.

One, choose the appropriate molding equipment, reasonable process conditions were determined, if small injection molding machine can’t satisfied requirements, is too large and waste of energy, and will be damaged due to improper clamping force adjusting mold or template, and lower the efficiency of injection machine at the same time, should according to the largest injection quantity, effective distance rod, mold installation dimensions shown on the template, the maximum modulus thick, thick minimum modulus, Template schedule, the ejection way, ejection stroke, injection pressure and clamping force of checks, such as Men required rear can use process conditions of reasonable it is also one of the content of the correct use of mould, clamping force is too large, high injection pressure, injection rate is too fast, mold temperature is too high will damage to the service life of the mold

Two, after the mold is installed on the injection machine, it is necessary to first enter the empty mold to observe whether the operation of each part is flexible, whether there is abnormal phenomenon, the ejection stroke, the opening stroke is in place, whether the mold surface is closely consistent when closing the mold, whether the pressing plate screw is tightened, etc

Three, when the mold is used, the normal temperature should be maintained, and the temperature should not be cold or warm. Working at the normal temperature can prolong the service life of the mold

Four, the sliding parts on the mold, such as guide column, back needle, push rod, core, etc., should be observed at any time, regular inspection, timely scrub and add lubricating oil, especially in summer when the temperature is high, at least two oil per shift, to ensure that these sliding parts are flexible movement, prevent tight biting death

Five, each time before clamping, all should pay attention to: whether the cavity is clean, absolutely do not leave residual products, or any other foreign matter, do not use hard tools to clean up, in order to prevent the surface of the cavity

For molds with special requirements on the surface of the cavity, the surface roughness Ra is less than or equal to 0.2cm. It is absolutely not allowed to be wiped by hand or with cotton wire.

Seven, the cavity surface to be cleaned regularly, injection mold in the molding process will often decompose the low molecular compound corrosion mold cavity, make the bright cavity surface gradually become dim and dull and reduce the quality of products, so the need for regular scrub, scrub can use alcohol or ketone preparations after scrub to dry in time.

Eight, leave the need to temporarily stop operation, should put on the mold closed, don’t let the cavity and core are exposed, in case of accidental damage, downtime is expected to more than 24 hours, to be in the cavity and core surface spray anti-rust oil or release agent, especially in the wet and humid areas, short time to also want to do the antirust processing surface quality of the water vapor in the air can make the mould cavity is reduced, When the surface quality of the product drops and the mold is used again, the oil on the mold should be removed and cleaned before it can be used. The compressed air drying required by the mirror surface is then dried with hot air. Otherwise, it will exude and cause defects in the product when forming

After temporary shutdown, start the machine. After opening the mold, check whether the slider limit is moved. In short, be careful before starting the machine and do not be careless

In order to extend the service life of the cooling channel, when the mold is stopped, the water in the cooling channel should be immediately removed with compressed air, put a small amount of oil into the nozzle, and then blow with compressed air to make all the cooling pipelines have a layer of rustproof oil

work carefully check the working state of each control unit in the fight auxiliary system exception occurs, heating and maintenance of the control system for hot runner mould is particularly important at the end of each production cycle, to stick heater, band heater and thermocouple is the mother into the line measurement, and compared with the technical specifications of the mould material, to ensure that its function in good condition at the same time, The control loop may be tested by ammeter installed in the loop. The oil in the hydraulic cylinder used for core pulling may be emptied as much as possible, and the nozzle is sealed to avoid leakage of hydraulic oil or contamination of the surrounding environment during storage and transportation

If the mold makes abnormal sound or other abnormal conditions are heard during production, the machine should be shut down immediately to check the mold. The maintenance personnel should inspect the normal working molds in the workshop, and deal with the abnormal phenomena in time

Thirteen, the operator in the shift, in addition to the handover production, process critical records, the use of the mold should also have a detailed explanation

when the mould finished products production quantity, the plane should change other mold, mold cavity should be coated with anti-rust agent, in the mold their attachment to the mold maintenance, with the last one in the production of qualified products as samples together to maintain member in addition, should also be sent to a list of mold used, fill in the mold on any machine, dong zhong from, What is the total number of products produced? Is the mold in good condition? If there is any problem with the mold, what problems exist in the mold should be filled in the use form, and specific requirements for modification and improvement should be put forward

sets up the mold base, should be set of personnel management, and establish the mold file, possible to mold computer management mold library should choose the moisture little ventilation, temperature should be kept below 70%, if the humidity is over 70%, the mold is easy to rust, mold shelves should be stored, pay attention to corrosion resistance, dustproof, etc to label needs to be repaired or completed repair, maintenance.

Welcome to contact TKB Mold China to update you more information about injection mold maintainence.

Precedente:Requisiti di stampaggio e stampaggio ad iniezione di plastica ad alta lucentezza

Prossimo: Punti chiave durante l'assemblaggio di stampi ad iniezione di plastica

-

Wholesale high quality Gate Injection Molding: A Revolutionary Technique for Precision Manufacturing

2023-8-19

Introduction In the realm of manufacturing, precision and efficiency are paramount. Companies relentlessly strive to dev...

Visualizza dettagli -

Manufacturing High-Quality Plastic Pallet Moulds for Efficient Storage Solutions

2023-9-5

Introduction: With the increasing demand for storage solutions in various industries, the need for high-quality plastic ...

Visualizza dettagli -

Creating a Plastic Pallet Mould: A Comprehensive Guide

2023-6-17

Plastic pallets are becoming increasingly popular in manufacturing, shipping, and distribution industries due to their d...

Visualizza dettagli -

Designing an Efficient Plastic Bottle Crate Mold: A Comprehensive Guide

2023-7-28

Introduction Plastic bottle crates are widely used in various industries for the storage and transportation of bottles. ...

Visualizza dettagli -

Key Components of an Injection Molding Machine

2023-6-30

Injection molding is a widely used manufacturing process for producing plastic parts in large quantities. It involves in...

Visualizza dettagli -

Mold Design facture: Creating Perfect Molds for Your Manufacturing Needs

2023-6-2

Mold design is a crucial part of manufacturing. Creating a perfect mold requires a deep understanding of the manufacturi...

Visualizza dettagli