Chair Mould for Injection Moulding Process

A chair is an essential piece of furniture in any home or office. It provides a comfortable place to sit and relax or work. The process of making a chair involves several steps, including the design, prototyping, and manufacturing. One critical aspect of chair manufacturing is the use of a chair mould for injection moulding.

Injection moulding is a manufacturing process used to create parts or products by injecting molten material into a mould. This process is used to produce a wide range of products, including chairs. Chairs made through injection moulding are known for their high durability, precision, and quality.

To create a chair mould for injection moulding, several steps need to be followed. The first step is the design process. The design of the mould depends on the design of the chair. The design process involves creating a 3D model of the chair using computer-aided design (CAD) software. The 3D model is used to create a mould that meets the requirements of the chair\’s design.

After the design process, the next step is the prototyping process. In this step, a prototype of the chair is created using the 3D model. The prototype is used to test the design. Any necessary modifications are made to the design based on the results of the prototype testing.

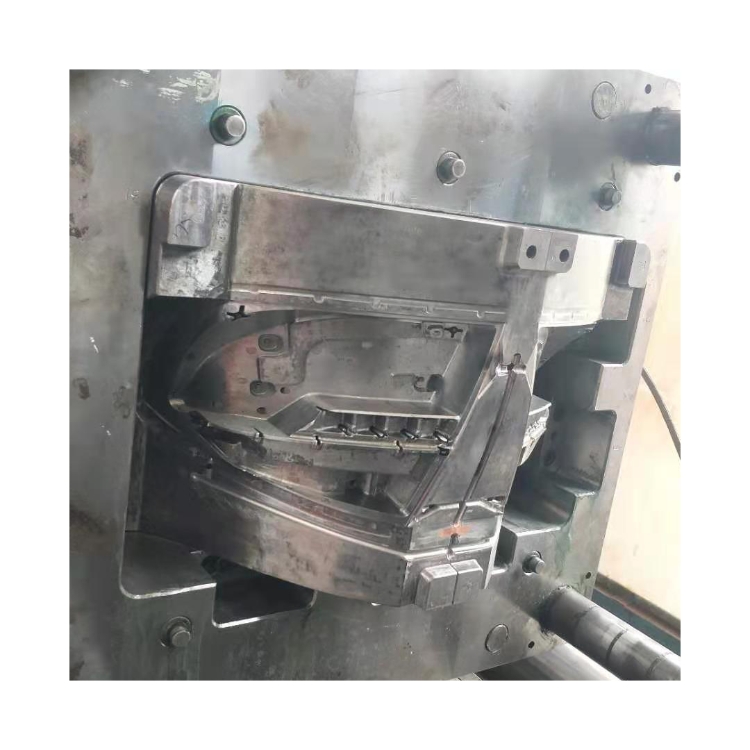

The next step is the manufacturing process. In this step, the mould is created using high-quality materials. The mould is made by cutting or carving the desired shape out of a block of metal. The block of metal is then heated to make it malleable. The mould is then created by pouring or injecting molten metal into the carved shape.

Once the mould is created, it is ready for injection moulding. Injection moulding involves injecting molten material, mostly plastic, into the mould. The molten material is then allowed to cool and solidify, taking the shape of the mould. The mould is then opened, and the newly formed chair is removed.

One critical aspect of chair moulds for injection moulding is the need for precision. The mould must be made to exact specifications to ensure the chair\’s quality and durability. Any deviation from the design can result in an inferior product.

In conclusion, chair moulds for injection moulding are an essential aspect of chair manufacturing. The process involves several steps, including the design, prototyping, manufacturing, and injection moulding. The mould must be made to exact specifications to ensure the quality and durability of the final product. Injection moulding is a reliable and efficient way to produce chairs with high precision and quality.

Precedente:Injection Chair Mould – The Ultimate Solution for High-Quality Chairs

Prossimo: “Creating High-Quality Home Appliance Molding Parts”

-

Analysis of the manufacturing process and quality control points of high-precision automotive molds

2024-12-18

The manufacturing process of high-precision automotive molds is complex and delicate, and the quality control points are...

Visualizza dettagli -

Professional Plastic Molding Services for Large-Scale Projects

2023-6-9

Plastic molding is an essential process in the manufacturing industry that is used to create plastic products of various...

Visualizza dettagli -

L'analisi del flusso di stampa può salvare il design dello stampo a iniezione

2022-8-4

Una delle chiavi per ottenere parti stampate a iniezione in plastica di qualità sono gli stampi di precisione, che possono produrre le stesse parti su...

Visualizza dettagli -

Enhance the Look and Feel of Your Space with Plastic Moulded Chairs

2023-6-10

Plastic moulded chairs have been around for decades, and their popularity has only grown over the years. They are inexpe...

Visualizza dettagli -

Injection Mold Design Engineering: Optimizing Efficiency and Quality in Manufacturing Processes

2023-6-7

The injection mold design engineering is a critical aspect of modern manufacturing processes. It involves developing and...

Visualizza dettagli -

Parti di stampaggio ad iniezione

2023-4-22

Injection molding is a manufacturing process used to create parts by injecting molten material into a mold. This process...

Visualizza dettagli