Aerospace Mold: Precision Engineering for the Aerospace Industry

Aerospace Mold: Precision Engineering for the Aerospace Industry

The aerospace industry requires products that are designed and manufactured with the highest levels of precision. This is where aerospace mold technology comes into play. Aerospace molds are specifically designed to create parts and components that meet the demanding requirements of the aerospace industry. In this article, we will explore the importance of aerospace mold technology and how it is used in the aerospace industry.

What is Aerospace Mold Technology?

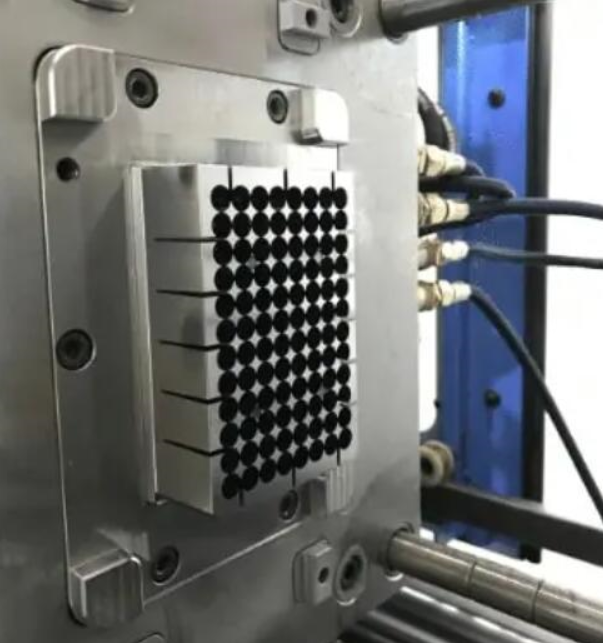

Aerospace mold technology involves the use of precision engineering techniques to create molds that are capable of producing aerospace components and parts that meet the exacting standards of the industry. These molds are designed using Computer-Aided Design (CAD) software, which allows engineers to create precise 3D models of the components that need to be manufactured. The molds are then created using Computer Numerical Control (CNC) machines that use the CAD data to produce the mold with the highest level of accuracy.

The Importance of Precision in Aerospace Manufacturing

Precision is a crucial element in aerospace manufacturing. The components and parts used in aircraft need to be made to exact specifications to ensure that they are safe and reliable. Even the slightest deviation from the required specifications can have serious consequences, including catastrophic failure.

This is why aerospace mold technology is so important. By using precision engineering techniques, aerospace molds can create parts and components that meet the exacting standards of the aerospace industry. These molds are designed to produce parts with extremely tight tolerances, ensuring that they are made to the required specifications.

How Aerospace Molds are Used in the Aerospace Industry

Aerospace molds are used in a variety of ways in the aerospace industry. They are used to create components and parts for everything from commercial airliners to military fighter jets. Some of the most common uses of aerospace molds include:

1. Engine Components: Aerospace molds are used to create a variety of engine components, including turbine blades, compressor blades, and combustion chambers. These components must be made to extremely tight tolerances to ensure that they are capable of withstanding the extreme temperatures and pressures of the aircraft engine.

2. Structural Components: Aerospace molds are also used to create structural components for aircraft. These components include wing spars, fuselage sections, and landing gear components. These parts must be made to exacting standards to ensure that they are strong and reliable.

3. Interior Components: Aerospace molds are also used to create a variety of interior components for aircraft. These components include cabin panels, overhead bins, and lavatory components. These parts must be made to exacting standards to ensure that they are safe and comfortable for passengers.

Conclusion

Aerospace mold technology is a crucial element in the aerospace industry. By using precision engineering techniques, aerospace molds can create parts and components that meet the exacting standards of the industry. These molds are used to create a variety of components and parts for aircraft, including engine components, structural components, and interior components. With the use of aerospace molds, the aerospace industry can continue to produce safe and reliable aircraft that meet the demands of passengers and military personnel alike.

Precedente:Designing High-Quality Electronics Mold: Tips and Techniques

Prossimo: Plastic Injection Molding: The Process and Applications

-

Creating Innovative Electronics: The Art of Electronics Mold

2023-7-11

Introduction: The world of electronics has witnessed significant advancements in recent years. The rapid pace of technol...

Visualizza dettagli -

Manufacturing a Round Plastic Pail Mould for Efficient Storage Solutions

2023-8-13

Introduction: Plastic pails have become an indispensable product in various industries, providing efficient storage solu...

Visualizza dettagli -

Injection Molding Parts: Creating High-Quality Plastic Products

2023-5-15

Injection molding is a manufacturing process used to produce a wide range of plastic parts and products. This process in...

Visualizza dettagli -

Medical injection molds: precision tools for shaping medical health

2024-12-26

In today's rapidly changing medical technology, medical injection molds, as the core tools in medical device manufacturi...

Visualizza dettagli -

Plastic Injection Mold Machine: Efficient Manufacturing Solution

2023-4-28

Plastic injection molding is a manufacturing process that involves the creation of intricate plastic parts by injecting ...

Visualizza dettagli -

Industrial Molding Parts: Enhancing Manufacturing Efficiency and Productivity

2023-4-28

Industrial molding parts are essential components in the manufacturing industry. These parts are designed to enhance eff...

Visualizza dettagli