Achieving Precision and Durability: Aerospace Molding Parts for the Future

Achieving precision and durability in aerospace molding parts is crucial for the success of any aerospace project. With the increasing need for better performance and safety in the aerospace industry, it is important to have reliable and high-quality molding parts that can withstand extreme conditions. In this article, we will explore the challenges of aerospace molding parts and how manufacturers are addressing them to meet the demands of the future.

The challenges of aerospace molding parts

Aerospace molding parts face a number of challenges due to the harsh conditions they are subjected to. These include high temperatures, pressure changes, and exposure to chemicals and radiation. In addition, aerospace molding parts must meet strict safety and reliability standards to ensure that they perform as expected in the field.

One of the biggest challenges of aerospace molding parts is achieving precision. Aerospace parts are required to be manufactured to very tight tolerances, which can be difficult to achieve with traditional molding methods. The parts must also be able to withstand high stress and pressure without deforming or cracking. This requires a combination of advanced materials, design, and manufacturing techniques.

Another challenge is durability. Aerospace parts must be able to withstand long periods of use without degrading. This means that they must be resistant to wear, corrosion, and fatigue. It also means that they must be able to withstand extreme temperatures, pressure changes, and other environmental factors that can cause damage over time.

Manufacturing solutions for aerospace molding parts

To meet the challenges of aerospace molding parts, manufacturers are turning to advanced materials, design, and manufacturing techniques. One of the most promising materials is composites, which offer high strength-to-weight ratios and excellent durability. Composites can be molded to very tight tolerances and can withstand extreme conditions without degrading.

Manufacturers are also using advanced design tools such as computer-aided design (CAD) and finite element analysis (FEA) to optimize the design of aerospace molding parts. These tools allow designers to simulate the performance of the parts under various conditions and make changes to the design before manufacturing begins. This helps to reduce the risk of failure and improve the overall performance of the parts.

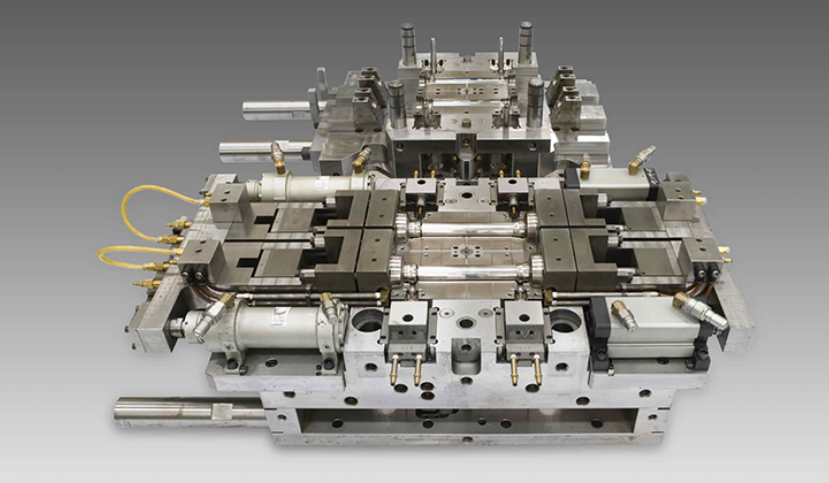

In addition, manufacturers are using advanced molding techniques such as injection molding and compression molding to achieve precision and durability in aerospace molding parts. These techniques allow for the creation of complex shapes and tight tolerances that are difficult to achieve with traditional molding methods. They also allow for the use of advanced materials such as composites and thermoplastics.

Conclusion

Achieving precision and durability in aerospace molding parts is essential for the success of any aerospace project. With the increasing demands for better performance and safety in the aerospace industry, manufacturers are turning to advanced materials, design, and manufacturing techniques to meet these challenges. By using composites, advanced design tools, and advanced molding techniques, manufacturers are able to create high-quality aerospace molding parts that can withstand extreme conditions and meet the demands of the future.

Precedente:China Aerospace Molding Parts – Crafting Precision Components for Aviation and Space Applications

Prossimo: Automotive Mold: Design, Production, and Application

-

Manufacturing a Round Plastic Pail Mould: A Comprehensive Guide

2023-7-4

Introduction: Plastic pails are widely used containers in various industries, including food processing, chemicals, and ...

Visualizza dettagli -

Gate Injection Molding Technology: Double Improvement in Quality and Efficiency

2024-4-27

In today's rapid development of manufacturing industry, Gate Injection Molding technology is becoming a key technology t...

Visualizza dettagli -

China Designing an Injection Chair Mould: A Comprehensive Guide

2023-8-4

Introduction: Injection molding is a widely used manufacturing process for producing plastic products. The process invol...

Visualizza dettagli -

Plastic Molds: Essential Tools in Industrial Manufacturing

2024-10-19

Plastic molds play an important role as key equipment in the production of plastic products. The following is a detailed...

Visualizza dettagli -

Molding Parts: Precision Engineering for Proven Performance

2023-7-13

In the world of manufacturing, precision engineering plays a crucial role in ensuring the performance and reliability of...

Visualizza dettagli -

Creazione di stampi automobilistici di alta qualità per la produzione di precisione

2023-4-13

The automotive industry is one of the most demanding manufacturing sectors in the world. With the constant need for inno...

Visualizza dettagli