Injection Molding Service: The Key to Efficient and Cost-Effective Production

Injection molding is a manufacturing process used to produce a wide range of plastic products. It is a highly efficient and cost-effective production method that allows for the creation of large quantities of identical products with consistent quality and minimal waste. Injection molding services can be used to produce a diverse range of products, ranging from simple household items to complex aerospace components. This article will explore the benefits of injection molding and discuss how injection molding services can help businesses achieve efficient and cost-effective production.

The Injection Molding Process

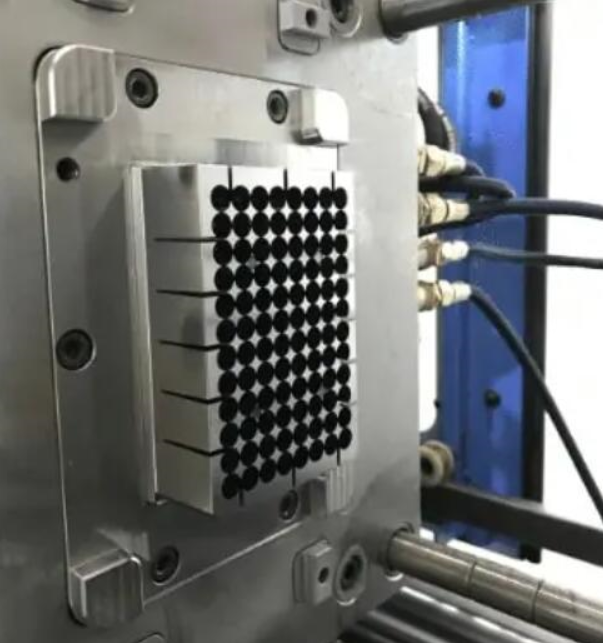

Injection molding is a complex process that involves the use of specialized machinery and materials. The process begins with the creation of a mold, which is then filled with molten plastic. The plastic is injected into the mold under high pressure and allowed to cool and solidify. Once the plastic has hardened, the mold is opened and the finished product is ejected.

One of the key advantages of injection molding is its ability to produce large quantities of identical products with consistent quality. This is because the process is highly automated and can be precisely controlled to ensure that each product meets the required specifications. Additionally, injection molding allows for the creation of complex shapes and designs that would be difficult or impossible to achieve with other manufacturing methods.

Benefits of Injection Molding

Injection molding offers a number of benefits over other manufacturing methods. These include:

1. Cost-effectiveness: Injection molding is a highly cost-effective production method, particularly for large quantities of products. This is because the process is highly automated and can be run continuously, minimizing labor costs and maximizing productivity.

2. Efficiency: Injection molding is a highly efficient production method, with cycle times typically ranging from a few seconds to a few minutes. This allows for the production of large quantities of products in a short amount of time.

3. Consistency: Injection molding allows for the production of identical products with consistent quality. This is because the process is highly automated and can be precisely controlled to ensure that each product meets the required specifications.

4. Design flexibility: Injection molding allows for the creation of complex shapes and designs that would be difficult or impossible to achieve with other manufacturing methods. This makes it an ideal choice for products with intricate shapes or design features.

Injection Molding Services

Injection molding services are available to businesses that need to produce large quantities of plastic products. These services can be used to produce a wide variety of products, including:

1. Consumer products: Injection molding services can be used to produce a wide range of consumer products, including household items, toys, and sporting goods.

2. Automotive components: Injection molding services can be used to produce a variety of automotive components, including dashboard components, door handles, and interior trims.

3. Medical devices: Injection molding services can be used to produce a variety of medical devices, including syringes, surgical instruments, and diagnostic equipment.

4. Aerospace components: Injection molding services can be used to produce a variety of aerospace components, including interior trims, ducts, and brackets.

Conclusion

Injection molding is a highly efficient and cost-effective production method that allows for the creation of large quantities of identical products with consistent quality. Injection molding services can be used to produce a wide variety of products, ranging from simple household items to complex aerospace components. Businesses that require large quantities of plastic products should consider using injection molding services to achieve efficient and cost-effective production.

Previous:Precision Injection Molded Parts: Achieving Consistent Quality and Efficiency

Next: Injection Mold Manufacturing: Streamlining the Production Process

-

Precision Mold Design: Innovative Technology Leads to Efficient Production

2024-6-28

In today's highly competitive manufacturing environment, the importance of precision mold design is becoming increasingl...

View details -

Why choose plastic parts injection molding and what are its advantages

2022-11-19

Plastic injection molding is a very common method of producing plastic parts that offers many advantages over other plas...

View details -

Medical injection molds: precision tools for shaping medical health

2024-12-26

In today's rapidly changing medical technology, medical injection molds, as the core tools in medical device manufacturi...

View details -

China Injection Mold Components: The Building Blocks of Precision Manufacturing

2023-5-27

Injection molding has revolutionized the manufacturing industry by enabling the production of complex and intricate part...

View details -

Precision Molded Parts for Home Appliances

2023-6-19

In today's world, home appliances have become an essential part of our daily lives. From washing machines to refrigerato...

View details -

top large plastic molds the best way to produce quality products

2022-11-3

Large plastic molds are a great way to produce quality products. They are often used in mass production settings, and ca...

View details