Procuring Large Plastic Molds: A Guide to Purchasing High-Quality Products

Introduction

Large plastic molds play a crucial role in the manufacturing industry, as they are used to produce a wide range of plastic products. The quality of these molds directly impacts the final product’s durability, performance, and aesthetics. Therefore, it is essential to ensure that you procure high-quality molds to achieve the desired results. This guide provides valuable insights into the factors to consider when purchasing large plastic molds.

1. Define Your Requirements

Before embarking on the procurement process, it is crucial to have a clear understanding of your requirements. Consider the type of plastic product you are manufacturing and its specific design requirements. Determine the size, complexity, and quantity of molds needed. Defining your requirements will help you communicate effectively with mold suppliers and ensure that you obtain the appropriate molds for your manufacturing needs.

2. Research and Identify Reputable Suppliers

Research is vital when it comes to finding reputable suppliers of large plastic molds. Look for suppliers with a proven track record of delivering high-quality molds to satisfied customers. Online platforms, industry networks, and trade shows can be excellent sources to identify reliable suppliers. Consider factors such as the supplier’s experience, expertise, production capacity, and the range of molds they offer. Additionally, read customer reviews and testimonials to gauge the supplier’s reputation and customer satisfaction.

3. Assess Mold Quality

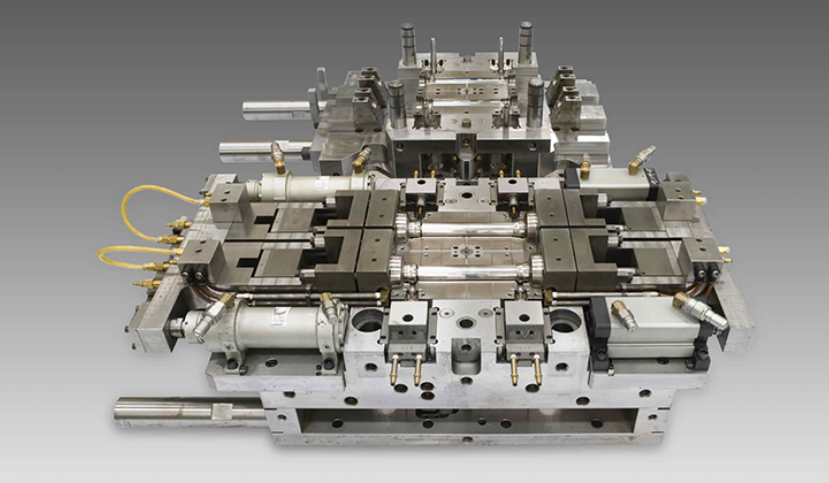

When purchasing large plastic molds, it is crucial to prioritize quality. The quality of the molds will significantly impact the quality of the final plastic products. Consider the materials used in mold production. High-quality molds are typically made from durable materials such as stainless steel or aluminum. These materials ensure the molds can withstand the rigors of the manufacturing process, reducing the risk of deformation or wear over time.

Additionally, examine the mold’s design and construction. Look for precision and attention to detail in the machining process. A well-designed mold will result in consistent and accurate plastic product production. Assess the mold’s cooling system, as an efficient cooling system contributes to shorter cycle times and improved productivity.

4. Manufacturing Capability and Capacity

Evaluate the supplier’s manufacturing capability and capacity. Large plastic molds require specialized equipment and expertise to ensure optimal quality. Inquire about the supplier’s mold manufacturing processes, machinery, and technical capabilities. Verify if they have the necessary infrastructure and resources to meet your specific requirements.

Consider the supplier’s production capacity to ensure they can handle your desired order quantity within the required timeframe. Adequate production capacity ensures timely delivery of molds and minimizes production delays.

5. Cost Considerations

While quality should be a top priority, it is essential to consider the cost of the molds. Obtain detailed quotations from multiple suppliers to compare prices. However, avoid choosing the cheapest option blindly, as it may compromise the quality of the molds. Instead, focus on obtaining the best value for your investment. Consider the supplier’s reputation, mold quality, and overall service when evaluating the cost.

Additionally, inquire about any additional costs, such as mold maintenance, repairs, or modifications. Proper maintenance and timely repairs are essential for prolonging the lifespan of the molds and ensuring consistent product quality.

6. Communication and Support

Effective communication with the mold supplier is crucial throughout the procurement process. Clear and open communication ensures that your requirements are understood and met. Discuss your expectations regarding product quality, delivery timelines, and any specific customization needs. A reliable supplier will provide regular updates on the manufacturing progress and address any concerns promptly.

Inquire about the supplier’s after-sales support, such as warranty, maintenance, and technical assistance. A supplier that offers comprehensive support demonstrates their commitment to customer satisfaction.

következtetés

Procuring large plastic molds is a significant investment for manufacturers. By following this guide and considering factors such as requirements, supplier reputation, mold quality, manufacturing capability, cost, and communication, you can make an informed decision when purchasing high-quality molds. Remember, choosing the right supplier is crucial for ensuring the consistent production of durable, high-performance plastic products.

Előző:Achieving Precision and Innovation: Aerospace Molding Parts

Következő: Creating a Plastic Paint Bucket Mould: A Step-by-Step Guide

-

Introduction to Insert Mold: A Comprehensive Guide

2023-7-29

Insert molding is a highly versatile and efficient manufacturing process that allows for the combination of multiple com...

Részletek megtekintése -

Plastic Molds: Essential Tools in Industrial Manufacturing

2024-10-19

Plastic molds play an important role as key equipment in the production of plastic products. The following is a detailed...

Részletek megtekintése -

Large Plastic Molds: Creating Big and Durable Products

2023-6-26

Plastic molds are widely used in the manufacturing industry to create different types of products. These molds are made ...

Részletek megtekintése -

Injection Molding Parts: Producing High-Quality Components with Precision and Efficiency

2023-5-16

Injection molding is a manufacturing process used to produce a wide range of plastic components. The process involves in...

Részletek megtekintése -

Medical Molding Parts: Precision and Quality for Critical Applications

2023-5-2

Medical molding parts play a critical role in the healthcare industry, where precision and quality are essential for the...

Részletek megtekintése -

Insert Mold: A Precision Tool for Shaping Industrial Innovation

2024-11-8

In modern manufacturing, insert molds play an increasingly important role as an efficient and precise molding tool. This...

Részletek megtekintése