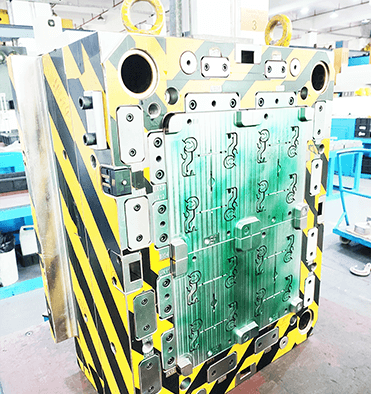

Home Appliance Molding Parts manufacture

Introduction

Home appliance molding parts are essential components of various household appliances such as refrigerators, washing machines, air conditioners, and many others. These parts are designed to improve the functionality, reliability, and durability of home appliances, ensuring that they meet the needs and expectations of consumers. In this article, we will explore the different types of home appliance molding parts, their functions, and the materials used in their production.

Types of Home Appliance Molding Parts

There are many different types of home appliance molding parts, each with a unique function and purpose. Some of the most common types of home appliance molding parts include:

1. Handles: Handles are an essential component of most home appliances, including refrigerators, ovens, and microwaves. They are typically made from plastic, metal, or a combination of both, and are designed to make it easier for users to open and close the appliance doors.

2. Control panels: Control panels are found on a wide range of home appliances, including washing machines, dryers, and dishwashers. They are typically made from plastic, and are designed to provide users with an easy-to-use interface for operating the appliance.

3. Housings: Housings are used to enclose the internal components of home appliances, including motors, compressors, and electronic components. They are typically made from plastic, and are designed to protect these components from damage and environmental factors.

4. Gaskets: Gaskets are used to seal the various components of home appliances, including doors and windows. They are typically made from rubber or silicone, and are designed to prevent air leaks and improve the energy efficiency of the appliance.

5. Fans: Fans are used to circulate air in home appliances, including refrigerators, air conditioners, and ovens. They are typically made from plastic and metal, and are designed to improve the performance and efficiency of the appliance.

Materials Used in Home Appliance Molding Parts

Home appliance molding parts are typically made from a variety of materials, depending on their function and purpose. Some of the most common materials used in the production of home appliance molding parts include:

1. Plastic: Plastic is the most common material used in the production of home appliance molding parts. It is lightweight, durable, and can be molded into a wide range of shapes and sizes.

2. Metal: Metal is also used in the production of home appliance molding parts, particularly for parts that require extra strength and durability, such as handles and hinges.

3. Rubber: Rubber is used in the production of gaskets and seals, as it is flexible, durable, and can withstand a wide range of temperatures and environmental conditions.

Conclusion

In conclusion, home appliance molding parts are essential components of various household appliances, designed to improve their functionality, reliability, and durability. They are made from a variety of materials, including plastic, metal, and rubber, and come in many different shapes and sizes. By understanding the different types of home appliance molding parts and the materials used in their production, consumers can make informed decisions when purchasing home appliances, ensuring that they meet their needs and expectations.

Previous:Plastic Injection Molding guide: The Process and Benefits

Next: China Aerospace Mold – Creating Precise and Reliable Components for the Aerospace Industry

-

Medical Molding Parts: Precision Manufacturing for Healthcare Needs

2023-4-21

Medical molding parts are an important component of the healthcare industry. These parts are used in various medical dev...

View details -

Manufacturing Efficiency Boosted with Injection Molded Plastic

2023-8-2

In recent years, the manufacturing industry has witnessed a significant boost in efficiency thanks to the adoption of in...

View details -

Injection Mold Design Engineering: A Comprehensive Guide

2023-6-12

Injection molding is a widely used manufacturing process in which plastic is melted and injected into a mold to produce ...

View details -

Achieving Precision and Efficiency with Aerospace Molding Parts

2023-7-4

Introduction: In the aerospace industry, precision and efficiency are critical factors for success. The ability to produ...

View details -

Creating a Custom Plastic Injection Mold for Your Product

2023-4-26

When it comes to manufacturing products, there are a lot of options available. One of the most popular methods is plasti...

View details -

Injection mold making: Precision processes shaping the future of industry

2024-12-31

In modern manufacturing industry, injection mold manufacturing occupies a pivotal position. From plastic products in dai...

View details