Production of Injection Crate Mould with High Precision and Quality

Injection moulding is a widely used manufacturing process for the production of various plastic components. One such component is the injection crate, which is used for the transportation and storage of goods in industries such as logistics, agriculture, and retail. The production of injection crate moulds requires high precision and quality to ensure the durability and functionality of the final product. This article will explore the process of producing injection crate moulds with a focus on achieving high precision and quality.

The first step in producing an injection crate mould is the design phase. This involves creating a 3D model of the desired crate using computer-aided design (CAD) software. The design should take into consideration factors such as the dimensions, weight capacity, and structural integrity of the crate. High precision in the design phase is crucial as any flaws or inaccuracies may result in defects in the final mould and ultimately affect the performance of the injection crate.

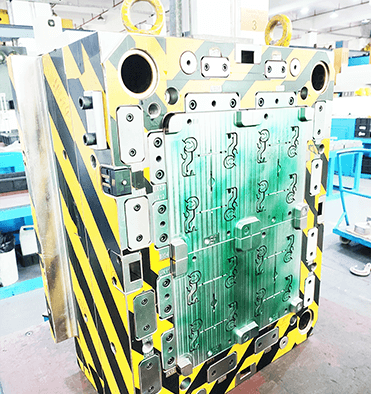

Once the design is finalized, the next step is to manufacture the mould itself. The mould is typically made from steel or aluminum, depending on the desired lifespan and cost considerations. High precision machining techniques such as CNC milling and electrical discharge machining (EDM) are employed to ensure the mould\’s dimensional accuracy and surface finish. These processes allow for tight tolerances and smooth surfaces, which are essential for producing high-quality injection crates.

After the mould is manufactured, it undergoes a series of tests and inspections to verify its precision and quality. This includes checking for any manufacturing defects, such as cracks or warping, as well as verifying the dimensions and specifications of the mould. These tests can be carried out using advanced measurement tools such as coordinate measuring machines (CMM) and optical scanners. Any issues identified during the testing phase are addressed and rectified to ensure that the final mould meets the required precision and quality standards.

Once the mould passes all the tests, it is ready for the injection moulding process. This involves injecting molten plastic material into the mould cavity under high pressure. The plastic material is then cooled and solidified, allowing it to take the shape of the mould cavity. High precision injection moulding machines are used to control the temperature, pressure, and speed of the injection process, ensuring consistent and accurate reproduction of the crate design.

After the injection moulding process is complete, the mould is opened, and the newly formed injection crate is removed. The crate undergoes a final inspection to ensure that it meets all the required specifications, including dimensional accuracy and structural integrity. Any defects or imperfections are addressed, and the crates that pass the inspection are ready for use in various industries.

In conclusion, the production of injection crate moulds requires high precision and quality to ensure the durability and functionality of the final product. Through careful design, precision manufacturing techniques, and rigorous testing, it is possible to achieve the desired level of precision and quality in the production of injection crate moulds. The use of advanced measurement tools and high precision injection moulding machines further enhances the accuracy and consistency of the manufacturing process. Ultimately, the production of injection crate moulds with high precision and quality plays a vital role in meeting the demands of industries that rely on these components for efficient transportation and storage of goods.

Précédent:Key Components of an Injection Molding Machine

Suivant: Creating a Plastic Fruit Crate Mold: A Guide to English Vocabulary and Techniques

-

Manufacturing a Round Plastic Pail Mould for Efficient Storage Solutions

2023-8-13

Introduction: Plastic pails have become an indispensable product in various industries, providing efficient storage solu...

Voir les détails -

Creating a Custom Plastic Injection Mold

2023-4-24

Creating a custom plastic injection mold is a complex and intricate process that requires careful planning, design, and ...

Voir les détails -

China Designing and Manufacturing a High-Quality Plastic Big Crate Mould

2023-7-16

Introduction Plastic big crates are essential items for industries such as logistics, warehousing, and transportation. T...

Voir les détails -

China Injection Mold Components: The Building Blocks of Precision Manufacturing

2023-5-27

Injection molding has revolutionized the manufacturing industry by enabling the production of complex and intricate part...

Voir les détails -

Injection mold making: Precision processes shaping the future of industry

2024-12-31

In modern manufacturing industry, injection mold manufacturing occupies a pivotal position. From plastic products in dai...

Voir les détails -

Plastic Bottle Crate Mould: An Overview

2023-6-11

Plastic bottle crates are essential in the logistics and packaging industries, as they provide a convenient way to trans...

Voir les détails