Comment choisir le bon grand moule en plastique

If you’re in the market for a large plastic mold, you’re probably wondering what you need to know before buying.

What is a large plastic mold?

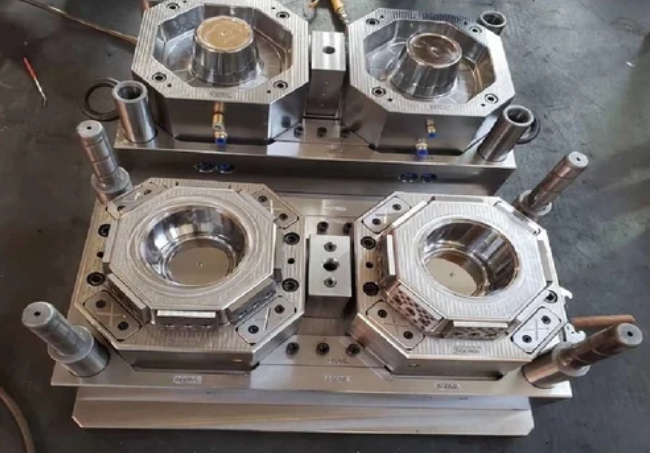

A plastic mold is a large, reusable mold used to make plastic items. They are often used to make large objects such as furniture, car parts and toys. There are two types of large plastic molds: injection molds and blow molds. Injection molds are the most common type of plastic mold. They are made by injecting molten plastic into a mold cavity. The plastic is then cooled and solidified to form the object. Blow molds are made by blowing molten plastic into a mold cavity. The plastic is then cooled and solidified to form the object.

What are the benefits of using large plastic molds?

There are several benefits to using large plastic molds. They are easier to work with than smaller molds, they are less likely to warp, and they produce a more consistent product. Also, large molds are less likely to be defective and easier to clean.

How do you choose the right large plastic mold for your needs?

There are a few things to consider when choosing the right large plastic mold for your needs. The first is what you will use the mold for. If you need a mold for casting your part, you need to find the right size and shape mold for your part. You also need to make sure the mold is made of a material that can withstand the heat and chemicals used in the casting process.

What are the maintenance and cleaning instructions for large plastic molds?

Care and cleaning instructions for plastic molds vary by plastic type. For large plastic molds, general precautions include avoiding sharp objects and cleaning with a soft cloth and mild detergent. To remove stubborn dirt or grease, you can use a small amount of isopropyl alcohol. When storing the mold, make sure it is completely dry to avoid moisture damage.

What are the best projects to use large plastic molds?

Many different types of projects can be made using large plastic molds. One of the most popular projects is creating concrete stepping stones. This is a great project to use with large plastic molds because it’s easy to do and the results are always very impressive.

What are the best projects to use large plastic molds?

Many different types of projects can be made using large plastic molds. One of the most popular projects is creating concrete stepping stones. This is a great project to use with large plastic molds because it’s easy to do and the results are always very impressive.

Choose tkb mold maker when you choose a large plastic mold, with more than 15 years of experience in the mold industry, TKB will provide you with mold design, material selection, prototyping, mold making, injection molding, related parts procurement, assembly and packaging. One-stop tooling and forming solutions. Welcome to Nous contacter.

-

Aerospace Mold: Precision Engineering for Superior Performance

2023-5-15

Aerospace mold manufacturing is a complex and highly specialized field that requires precision engineering for superior ...

Voir les détails -

Medical Molding Parts: Manufacturing Precision Components for the Healthcare Industry

2023-5-2

Medical molding parts are critical to the healthcare industry, as they play a significant role in ensuring the safety an...

Voir les détails -

Medical Molding Parts for Precision Healthcare Solutions

2023-4-19

Medical molding parts for precision healthcare solutions are essential components in modern medical devices and equipmen...

Voir les détails -

What is the process of plastic mold making?

2024-11-16

Plastic mold making is a complex and delicate process that involves multiple steps and multiple technologies. The core o...

Voir les détails -

Designing a Precision Plastic Crate Mould for Efficient Storage and Transportation

2023-6-13

In today's fast-paced world, efficient storage and transportation of goods are crucial for businesses to succeed. One of...

Voir les détails -

Exclusive English Offer: Injection Chair Mold

2023-7-1

Are you a furniture manufacturer looking for top-quality injection chair molds? Look no further! Our company is proud to...

Voir les détails