Creating High-Quality Automotive Molds for Precision Manufacturing

The automotive industry is one of the most demanding manufacturing sectors in the world. With the constant need for innovation and improvement, automotive manufacturers require precision-made parts that meet strict quality standards. Automotive molds play a critical role in producing these parts, and their quality is essential for achieving accuracy and consistency in manufacturing. In this article, we will explore the process of creating high-quality automotive molds for precision manufacturing.

Design and Engineering

The first step in creating high-quality automotive molds is design and engineering. Before any physical work begins, engineers use sophisticated software to create 3D models of the molds. These models allow designers to visualize the mold and make necessary adjustments before the process begins. The design process also includes selecting the appropriate materials for the mold. Factors such as the part’s shape, size, and material are all considered in the mold’s design.

Machining and Fabrication

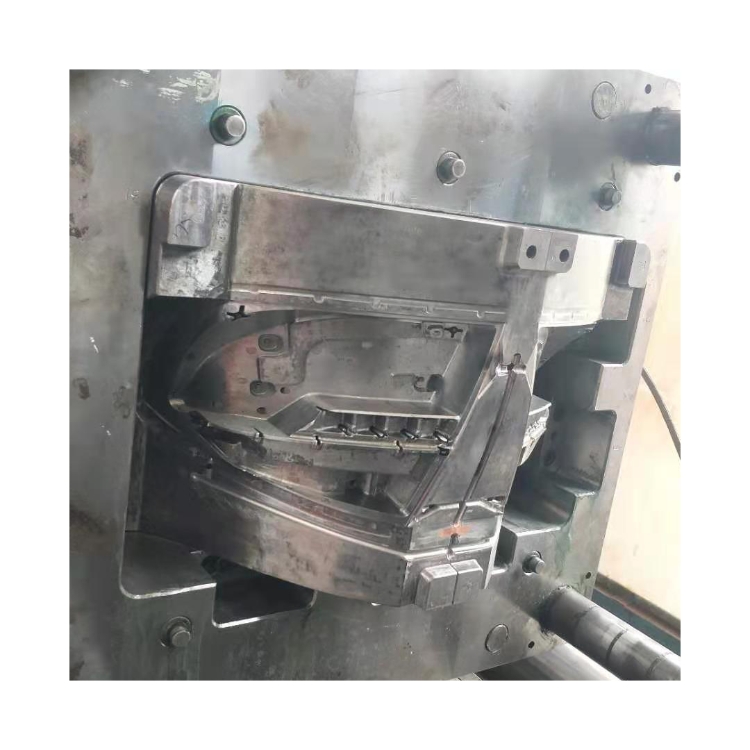

Once the design is finalized, the mold-making process begins with machining and fabrication. The mold’s raw material is typically a block of aluminum or steel. Using advanced cutting tools, the block is precisely cut into the desired shape of the mold. This process requires high levels of accuracy and attention to detail to ensure the mold’s dimensions are correct.

Next, the mold undergoes heat treatment to improve its strength and durability. This process involves heating the mold to a high temperature and then cooling it quickly. The result is a hardened mold that can withstand the pressure of the injection molding process.

Polishing and Finishing

After the mold has been machined and heat-treated, it undergoes polishing and finishing. This process involves removing any rough edges or imperfections in the mold’s surface. A high level of precision is required to ensure that the mold’s surface is smooth and free of defects. Any imperfections in the mold can cause defects in the parts produced, so this step is critical to ensuring high-quality molds.

Assembly and Testing

Once the mold has been polished and finished, it is ready for assembly. This process involves fitting the mold’s components together to create a working mold. The mold is then tested to ensure it produces parts that meet the desired specifications. This step is crucial to ensuring that the mold is ready for use in precision manufacturing.

Conclusion

Creating high-quality automotive molds for precision manufacturing requires a high level of skill and attention to detail. The process involves design and engineering, machining and fabrication, polishing and finishing, and assembly and testing. By following these steps, manufacturers can create molds that produce parts of the highest quality, ensuring the automotive industry meets its exacting standards.

Précédent:Automotive Mold: The Key to Efficient and Cost-effective Car Production

Suivant: Création de grands moules en plastique pour une fabrication efficace

-

Designing a High-Quality Plastic Injection Chair Mould for Ultimate Comfort

2023-7-8

Introduction: Chairs are an essential piece of furniture found in homes, offices, and various public spaces. The design ...

Voir les détails -

China Mold Design: Key Factors to Consider for Successful Production

2023-5-12

Mold design is a critical component of the manufacturing process. It involves creating a design for the mold that will b...

Voir les détails -

Designing the Perfect Plastic Crate Mould: A Comprehensive Guide

2023-9-20

Introduction Plastic crates have become an essential tool in various industries, including logistics, agriculture, and r...

Voir les détails -

Analysis of the manufacturing process and quality control points of high-precision automotive molds

2024-12-18

The manufacturing process of high-precision automotive molds is complex and delicate, and the quality control points are...

Voir les détails -

Creating High-Quality Plastic Products with Precision Plastic Moulding Technology

2023-6-18

Plastic moulding technology has revolutionized the manufacturing industry, making it possible to produce high-quality pl...

Voir les détails -

Injection mold: precision tool for plastic product manufacturing

2024-9-20

As the core equipment in the production of plastic products, injection mold is an indispensable part of modern industria...

Voir les détails