Molding Parts: Creating Precision Components

In the world of manufacturing, precision is paramount. Creating components with high accuracy and consistency is vital for industries such as automotive, aerospace, and medical. One of the most common methods employed to achieve such precision is molding.

Molding is a manufacturing process that involves shaping a material into a specific form by using a mold. It allows for the production of complex parts with consistent dimensions and intricate details. Molding parts are widely used in various industries due to their durability, cost-effectiveness, and ease of mass production.

There are several types of molding processes, each suitable for different applications. Injection molding, for instance, is commonly used to create plastic components. It involves injecting molten plastic into a mold cavity under high pressure. The plastic solidifies inside the mold, taking the desired shape. Injection molding offers high precision, tight tolerances, and the ability to produce large quantities of parts rapidly.

Another widely used molding process is compression molding. This method is particularly suitable for molding rubber, thermosetting plastics, and composites. Compression molding involves placing a preheated material into a heated mold cavity. The material is then compressed under high pressure until it takes the shape of the mold. This process enables the creation of parts with intricate details, good dimensional stability, and excellent surface finish.

For certain applications, where strength and durability are crucial, the process of transfer molding is employed. It is similar to compression molding but involves the use of a plunger to force the material into the mold cavity. Transfer molding is commonly used for manufacturing electrical connectors, encapsulated components, and other small parts.

In addition to these three main molding processes, there are other specialized methods such as blow molding, extrusion molding, and rotational molding. Each process has its own advantages and is chosen based on the specific requirements of the part being produced.

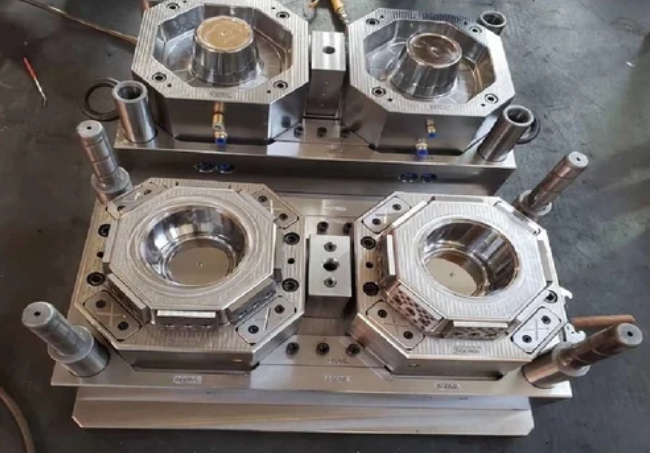

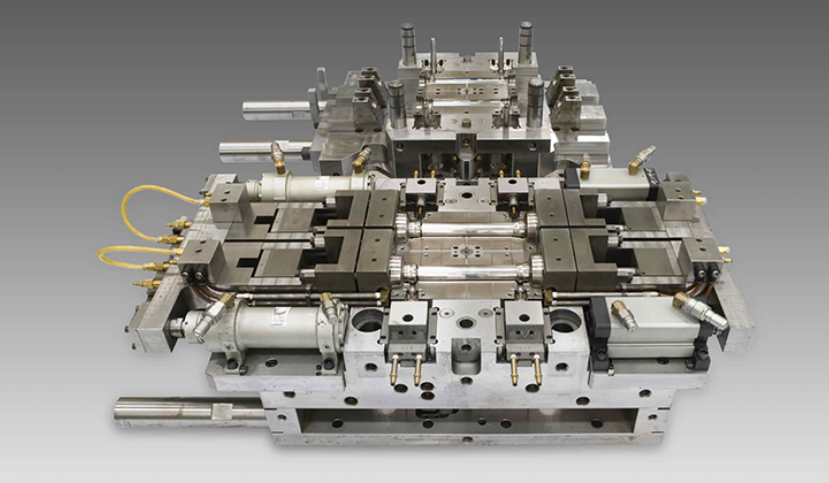

Regardless of the chosen molding process, precision is achieved through careful design and engineering. The mold used plays a crucial role in determining the final quality of the part. Molds are typically made from high-quality materials such as steel or aluminum and are precisely machined to the desired shape. The design of the mold must account for factors such as shrinkage, warping, and cooling to ensure that the final part meets the required specifications.

To create precision components, the selection of the molding material is also crucial. Different materials have different properties, such as strength, flexibility, and heat resistance. The material must be chosen based on the specific application and performance requirements of the part. Additionally, advancements in material science have led to the development of specialized materials with enhanced properties, such as high heat resistance or chemical resistance.

In recent years, the use of computer-aided design (CAD) and computer-aided manufacturing (CAM) systems has revolutionized the field of molding. These technologies enable designers to create intricate 3D models of parts and simulate the molding process before actual production. By conducting virtual tests and optimizations, manufacturers can minimize errors, reduce costs, and improve the overall quality of the final product.

En conclusión, molding parts are essential in many industries due to their precision, consistency, and cost-effectiveness. The various molding processes offer different advantages depending on the application and requirements of the part. With advancements in materials and technology, the production of precision components continues to evolve, allowing for the creation of complex and durable parts that drive innovation and progress in numerous sectors.

Anterior:Purchasing Large Plastic Molds: A Comprehensive Guide to Procuring High-Quality Mold Solutions

-

Creating the Perfect Plastic Chair Mold: A Step-by-Step Guide

2023-8-16

Introduction: Plastic chairs have become an essential part of our daily lives, whether at home, offices, or public place...

Ver detalles -

Industrial Molding Parts manufacture: Essential Components for Manufacturing Success

2023-5-12

Industrial molding parts play a crucial role in the manufacturing process as they are essential components that are used...

Ver detalles -

Designing a High-Quality Plastic Chair Mould for Efficient Production

2023-6-11

Plastic chairs are one of the most common pieces of furniture in the world, used in homes, offices, and public spaces. T...

Ver detalles -

What is the process of plastic mold making?

2024-11-16

Plastic mold making is a complex and delicate process that involves multiple steps and multiple technologies. The core o...

Ver detalles -

Plastic Molds: Essential Tools in Industrial Manufacturing

2024-10-19

Plastic molds play an important role as key equipment in the production of plastic products. The following is a detailed...

Ver detalles -

Chair Mould for Injection Moulding Process

2023-6-15

A chair is an essential piece of furniture in any home or office. It provides a comfortable place to sit and relax or wo...

Ver detalles