Piezas médicas moldeadas para soluciones de atención médica de precisión

Medical molding parts for precision healthcare solutions are essential components in modern medical devices and equipment. These parts are manufactured to meet the high standards of the healthcare industry, which requires precision, accuracy, and reliability in the products used to diagnose and treat various medical conditions. Medical molding is an advanced manufacturing process that produces complex parts with intricate designs and tight tolerances. This process involves the use of specialized materials and equipment, and it requires extensive knowledge and experience to produce high-quality medical molding parts. In this article, we will explore the importance of medical molding parts for precision healthcare solutions and the benefits they offer to patients and healthcare providers.

Importance of Medical Molding Parts for Precision Healthcare Solutions

Medical molding parts play a critical role in the development of modern medical devices and equipment. These parts are used in a wide range of applications, including surgical instruments, diagnostic devices, drug delivery systems, and implantable devices. Medical molding parts are designed to meet the unique requirements of each application, and they are manufactured to the highest standards of quality and reliability.

Precision is essential in the healthcare industry, where accuracy can mean the difference between life and death. Medical molding parts are manufactured to tight tolerances, ensuring that they meet the precise specifications required for each application. The use of specialized materials and advanced manufacturing technology ensures that medical molding parts are durable, reliable, and able to withstand the harsh conditions of the healthcare environment.

Benefits of Medical Molding Parts for Precision Healthcare Solutions

The use of medical molding parts in precision healthcare solutions offers several benefits to patients and healthcare providers. These benefits include:

1. Improved Patient Outcomes: Medical molding parts are designed to meet the unique requirements of each application, ensuring that they provide optimal performance and accuracy. This results in improved patient outcomes, as medical devices and equipment are able to diagnose and treat medical conditions more effectively.

2. Reduced Costs: Medical molding parts are manufactured to tight tolerances, ensuring that they meet the precise specifications required for each application. This results in reduced costs, as medical devices and equipment are less likely to fail or require repair, reducing the need for costly replacements and repairs.

3. Increased Efficiency: Medical molding parts are designed to be efficient and effective, ensuring that medical devices and equipment operate at peak performance. This results in increased efficiency, as healthcare providers are able to diagnose and treat medical conditions more quickly and effectively.

4. Enhanced Patient Safety: Medical molding parts are manufactured to the highest standards of quality and reliability, ensuring that they are safe and effective for use in the healthcare environment. This results in enhanced patient safety, as medical devices and equipment are less likely to cause harm or injury to patients.

conclusión

Medical molding parts for precision healthcare solutions are essential components in modern medical devices and equipment. These parts are designed to meet the unique requirements of each application, ensuring that they provide optimal performance and accuracy. The use of specialized materials and advanced manufacturing technology ensures that medical molding parts are durable, reliable, and able to withstand the harsh conditions of the healthcare environment. The benefits of medical molding parts for precision healthcare solutions include improved patient outcomes, reduced costs, increased efficiency, and enhanced patient safety.

Anterior:Injection Molding Parts – Manufacturing High Quality Components

Próximo: Piezas de moldeo por inyección: una guía para la fabricación

-

2023-7-2

The world of design is constantly evolving, and one area that has seen significant advancements is furniture design. Cha...

Ver detalles -

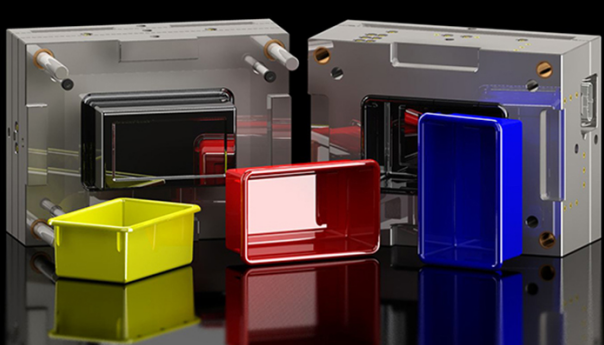

China Injection Crate Mould: Creating Efficient and Durable Storage Solutions

2023-8-8

Introduction In today's fast-paced world, efficient and durable storage solutions are essential for businesses and indiv...

Ver detalles -

Injection Molding Parts guide: Essential Components for High-Quality Products

2023-5-7

Injection molding is an essential process used in the manufacturing industry. It involves the injection of molten materi...

Ver detalles -

How are precision moulds made?

2024-12-3

In the vast field of manufacturing, precision moulds play a vital role. Not only are they key tools in the production of...

Ver detalles -

2023-4-27

Creating custom plastic injection molds is a crucial process in manufacturing plastic parts. By developing an injection ...

Ver detalles -

Achieving Precision and Efficiency with Aerospace Molding Parts

2023-7-4

Introduction: In the aerospace industry, precision and efficiency are critical factors for success. The ability to produ...

Ver detalles