Injection Molding Parts: Creating High-Quality Plastic Products

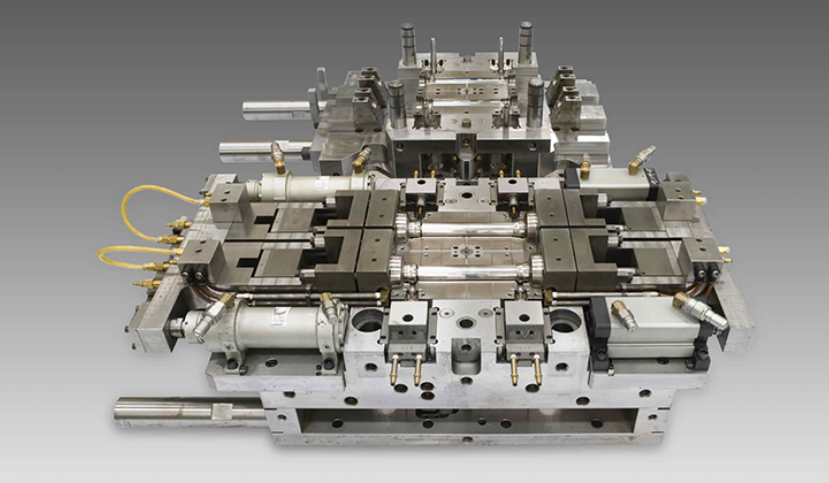

Injection molding is a manufacturing process used to produce a wide range of plastic parts and products. This process involves melting plastic pellets and injecting them into a mold, where they cool and solidify, forming the desired shape. Injection molding is a highly versatile and efficient method of producing high-quality plastic parts in large quantities.

The injection molding process begins with the preparation of the raw materials. Plastic pellets are loaded into a hopper and transported to the injection molding machine. The pellets are then melted and injected under pressure into a mold. Once the plastic has cooled and solidified, the mold is opened and the finished product is removed.

The quality of injection molding parts is determined by a number of factors, including the design of the mold, the quality of the raw materials, and the skill of the operator. For example, the design of the mold must be carefully thought out to ensure that the final product meets the desired specifications. The mold must also be properly maintained to ensure that it lasts for many cycles.

The quality of the raw materials is another important factor that affects the quality of injection molding parts. High-quality plastic pellets are essential for producing parts that are strong, durable, and resistant to wear and tear. The raw materials must also be free of contaminants, such as dirt and debris, that can compromise the integrity of the finished product.

The skill of the operator is also critical in producing high-quality injection molding parts. Experienced operators are able to adjust the parameters of the injection molding machine to ensure that the plastic flows into the mold evenly and without defects. They are also able to troubleshoot problems that may arise during the manufacturing process, such as mold warping or material degradation.

Injection molding is used to produce a wide range of plastic products, including automotive parts, medical devices, consumer goods, and electronic components. The process is highly efficient, with parts being produced quickly and at a relatively low cost. Injection molding is also environmentally friendly, as it produces minimal waste and does not require the use of harmful chemicals.

In conclusion, injection molding is a highly versatile and efficient method of producing high-quality plastic parts and products. The quality of injection molding parts is determined by a number of factors, including the design of the mold, the quality of the raw materials, and the skill of the operator. With proper attention to these factors, injection molding can be used to produce a wide range of products that meet the highest standards of quality and performance.

-

Plastic Molds: Essential Tools in Industrial Manufacturing

2024-10-19

Plastic molds play an important role as key equipment in the production of plastic products. The following is a detailed...

Ver detalles -

¿Qué es un molde de inyección médico?¿Por qué elegir un molde de inyección médico?

2022-12-2

En el cuidado de la salud, los productos médicos moldeados por inyección juegan un papel vital en el mantenimiento de la seguridad del paciente. Por eso es crucial...

Ver detalles -

Designing the Perfect Plastic Chair Mould: A Masterpiece of Innovation in English

2023-6-30

Plastic chairs have become an integral part of our daily lives. Whether it's at home, in the office, or even in public s...

Ver detalles -

Industrial Molding Parts for High-Quality Manufacturing

2023-5-11

Industrial molding is a process of manufacturing various parts and products by heating and shaping materials such as pla...

Ver detalles -

Understanding the Factors Affecting Injection Mold Costs

2023-7-30

Injection molding is a widely used manufacturing process in which molten material is injected into a mold cavity to crea...

Ver detalles -

Transforming the Manufacturing Industry with Industrial Mold Technology

2023-5-12

The manufacturing industry has undergone significant changes in the past few decades, thanks to advancements in technolo...

Ver detalles