Creating Quality Chairs: The Art of Chair Mould Making

Chairs are an essential part of our daily lives. We sit on them while working, eating, or relaxing. A good chair not only provides comfort but also adds style and elegance to a space. Behind the creation of every quality chair lies the art of chair mould making.

Chair mould making is a meticulous and intricate process that requires skill, precision, and attention to detail. It involves the creation of a mould, which serves as the foundation for producing multiple chairs with consistent quality.

The first step in chair mould making is the design phase. Skilled designers work closely with manufacturers to conceptualize and create chair prototypes. The design must take into consideration factors such as ergonomics, functionality, and aesthetics. Once the design is finalized, it is then transformed into a 3D CAD model.

From the 3D CAD model, a prototype is created using various techniques such as CNC machining or 3D printing. This prototype serves as a tangible representation of the final chair design and allows for further refinement and adjustments.

Once the prototype is approved, the chair mould making process begins. The first step is to create a master pattern. This is typically made from wood, foam, or a combination of materials. The master pattern is a highly detailed and precise replica of the final chair design.

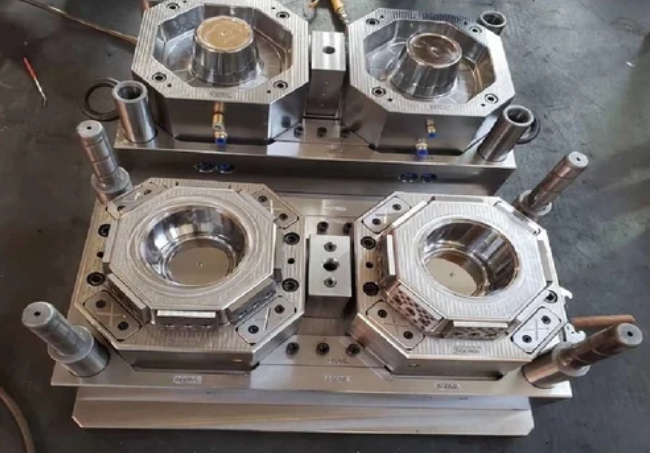

Using the master pattern, a mould is created. The mould is made from materials such as fiberglass, steel, or aluminum. The choice of material depends on factors such as the complexity of the chair design, the desired production volume, and the budget.

Creating a mould involves several steps. First, the master pattern is coated with a release agent to prevent it from sticking to the mould material. Then, layers of the mould material are applied, with each layer being carefully cured and reinforced. The mould is then allowed to cure and harden before being demolded.

Once the mould is ready, it is time for the actual chair production. The mould is filled with the desired material, such as plastic, fiberglass, or wood composite. The material is injected or poured into the mould cavity, taking the shape of the chair design. After a specified amount of time, the material is allowed to cool and solidify.

The final step in chair mould making is the demoulding process. The mould is opened, and the newly formed chair is carefully removed. Any excess material or imperfections are trimmed or sanded down. The chair is then inspected for quality, ensuring that it meets the desired specifications and standards.

Chair mould making is not a simple process. It requires a deep understanding of materials, design principles, and manufacturing techniques. Skilled craftsmen and engineers work together to ensure that every chair produced is of the highest quality and meets the expectations of both the manufacturers and the end-users.

In conclusion, chair mould making is an art that combines creativity, technical expertise, and craftsmanship. It is the foundation for creating quality chairs that are not only functional but also aesthetically pleasing. The attention to detail and precision involved in chair mould making ensure that each chair produced is a masterpiece in its own right. So, the next time you sit on a well-crafted chair, take a moment to appreciate the artistry behind its creation.

Anterior:Designing a High-Quality Plastic Vegetable Crate Mold: A Key to Efficient Produce Packaging

Próximo: Stylish and Durable Plastic Molded Chairs: Enhancing Comfort and Aesthetics

-

What is the process of plastic mold making?

2024-11-16

Plastic mold making is a complex and delicate process that involves multiple steps and multiple technologies. The core o...

Ver detalles -

Cómo el moldeo por inyección revolucionó la fabricación

2023-4-14

Injection molding is a manufacturing process that has revolutionized the way products are made. It is a process that inv...

Ver detalles -

China Plastic Injection Molding Machine wholesale

2023-4-27

A plastic injection molding machine is a machine used to create plastic products through the injection molding process. ...

Ver detalles -

Maintenance and Care of Electronic Plastic Molds

2024-6-7

In the electronics manufacturing industry, plastic molds are essential production tools. To ensure the efficient operati...

Ver detalles -

Does automotive mold technology unleash innovation?

2023-7-20

The automotive industry has always been at the forefront of innovation, constantly pushing the boundaries of technology ...

Ver detalles -

Automotive Parts Production with Injection Molding Technology

2023-5-31

Automotive parts production is a complex process that involves a variety of technologies and materials. One of the key t...

Ver detalles