Aerospace Mold: Precision Engineering for High-Flying Success

In the field of aerospace engineering, precision is of utmost importance. Whether it’s the design of aircraft or the manufacturing of their components, every detail must be meticulously planned and executed to ensure safe and efficient flight. One crucial aspect of this process is the creation of aerospace molds, which play a pivotal role in shaping various parts of an aircraft.

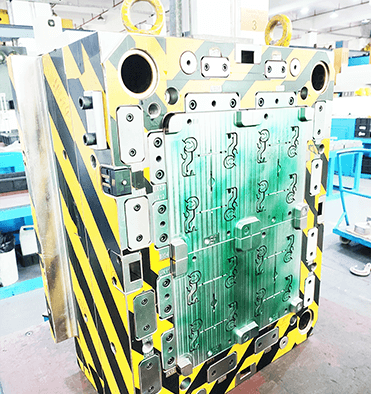

Aerospace molds are specialized tools used in the manufacturing process of aerospace components. These molds are typically made from high-quality materials such as steel or aluminum and are designed to withstand the high temperatures and pressures involved in aircraft production. The precision and accuracy of these molds are critical as they directly impact the performance and safety of the final product.

The creation of aerospace molds involves several stages, starting with the initial design. Engineers work closely with aerospace manufacturers to understand their specific requirements and create a mold design that meets their needs. This design phase includes careful consideration of factors such as the geometry and dimensions of the components, the materials to be used, and the manufacturing techniques involved.

Once the design is finalized, the mold-making process begins. This process can be complex and time-consuming, requiring the expertise of skilled engineers and technicians. The use of advanced computer-aided design (CAD) software and state-of-the-art machining tools allows for the precise production of aerospace molds. These tools enable engineers to create intricate and highly accurate molds that meet the strict quality standards of the aerospace industry.

One of the key challenges in aerospace mold manufacturing is ensuring that the final product meets the required tolerances. Aerospace components, such as turbine blades or fuselage sections, need to fit together seamlessly to ensure optimal performance. Any deviation from the specified dimensions can lead to significant issues during assembly and operation. Therefore, the manufacturing process must be closely monitored and controlled to maintain the desired level of precision.

To achieve this level of precision, aerospace mold manufacturers employ various techniques, including CNC machining, electrical discharge machining (EDM), and high-speed milling. These techniques enable the production of molds with very tight tolerances, ensuring the accurate replication of the desired component shape. Additionally, the use of advanced inspection tools, such as coordinate measuring machines (CMMs), allows for thorough quality control checks to ensure the molds meet the required specifications.

The aerospace mold industry is constantly evolving to keep pace with the advancements in aircraft design and technology. As aircraft become more complex and technologically advanced, the demand for highly precise and intricate molds continues to grow. This necessitates ongoing research and development efforts to improve mold design and manufacturing processes.

In recent years, additive manufacturing, also known as 3D printing, has emerged as a promising technology in the aerospace mold industry. This technology allows for the creation of complex mold geometries that were previously not feasible using traditional manufacturing methods. Additive manufacturing also offers the potential for faster and more cost-effective mold production, further enhancing its appeal in the aerospace industry.

The importance of precision engineering in aerospace mold manufacturing cannot be overstated. The accuracy of these molds directly affects the quality and performance of aircraft components, which, in turn, impact the safety and efficiency of air travel. As the aerospace industry continues to push the boundaries of innovation, the demand for highly accurate and reliable aerospace molds will only increase.

In conclusion, aerospace molds are integral to the success of the aerospace industry. The precision and accuracy of these molds play a crucial role in shaping various aircraft components. Through advanced design and manufacturing techniques, aerospace mold manufacturers strive to meet the demanding requirements of the industry. As technology advances, the aerospace mold industry will continue to evolve, ensuring that it remains at the forefront of precision engineering for high-flying success.

Anterior:English Injection: Chair Mold Offer

Próximo: Crafting the Perfect Crate Mould: Unlocking Efficiency and Precision

-

Is the rise of medical mold in healthcare facilities uncovering dangers?

2023-7-27

Introduction In recent years, healthcare facilities have been facing a growing concern in the form of medical mold. Mold...

Ver detalles -

Creating a Mold for a Crate: A Step-by-Step Guide

2023-12-27

Crate molds are essential tools in the manufacturing industry, used to create sturdy and durable crates for various purp...

Ver detalles -

Aerospace Molding Parts – English Title

2023-6-17

Aerospace molding parts play a crucial role in the aerospace industry, as they provide complex and highly accurate compo...

Ver detalles -

Injection mold making: Precision processes shaping the future of industry

2024-12-31

In modern manufacturing industry, injection mold manufacturing occupies a pivotal position. From plastic products in dai...

Ver detalles -

Transforming the Manufacturing Industry with Industrial Mold Technology

2023-5-12

The manufacturing industry has undergone significant changes in the past few decades, thanks to advancements in technolo...

Ver detalles -

Creación de moldes de inyección de calidad para la fabricación

2023-4-20

El moldeo por inyección es un proceso de fabricación popular que implica la creación de objetos 3D mediante la inyección de plástico fundido en...

Ver detalles