Metal insert mold: the core technical element of precision manufacturing

In the modern manufacturing industry that strives for high precision, high efficiency and versatility, metal insert molds, with their unique design concept, complex manufacturing process and excellent performance, have become the core technical elements in the field of precision manufacturing. This article will discuss the significance and technical characteristics of metal insert molds from three aspects.

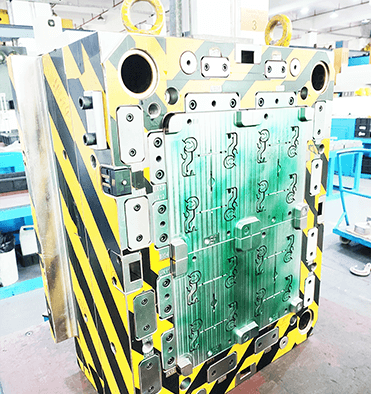

1. The Art of Precision Design: Ensuring the Perfect Fusion of Inserts and Plastics

The design of metal insert molds is a demonstration of the art of precision manufacturing. Designers must fully consider the interaction between inserts and plastic substrates, including differences in thermal expansion coefficients, shrinkage compensation, and the positioning stability of inserts in the plastic flow. Through precise dimensional calculations, complex flow channel design, and proper cooling system layout, mold designers aim to achieve seamless integration of inserts and plastic substrates to ensure that the final product not only meets functional requirements, but also has excellent visual quality. This design not only tests the professional skills of designers, but also reflects the combination of a deep understanding of material science, mechanical principles and injection molding processes.

2. The Challenge of Complex Manufacturing: High Precision Machining and Strict Quality Control

The manufacturing process of metal insert molds is full of technical challenges. The manufacturing accuracy of the mold directly affects the final quality of the product. Therefore, from material selection, rough machining, fine machining, heat treatment, assembly and debugging, each link must be strictly controlled to ensure the accuracy and durability of the mold. High-precision CNC machining equipment, advanced inspection technology and strict quality control process are the technical guarantee for the production of metal insert molds. In addition, facing insert molds with complex structures, such as multi-cavity, deep cavity, thin wall, etc., manufacturers also need to adopt special processing technology and process measures to overcome the processing difficulty and improve the molding ability and production efficiency of the mold.

3. The key to optimizing performance: improving product quality and production efficiency

Metal insert molds play an important role in improving product quality and production efficiency. By precisely controlling the position, shape and size of the insert, the mold can ensure the consistency and stability of the product and reduce the scrap rate and defective product rate. At the same time, reasonable mold structure and optimized injection molding process parameters can reduce production costs and improve production efficiency. In addition, metal insert molds also have good durability and maintainability, and can run stably on the production line for a long time, bringing continuous economic benefits to the company. Therefore, continuously optimizing mold design and improving mold manufacturing precision and performance are the keys to enhancing enterprise competitiveness and promoting industrial upgrading.

In summary, as a core technical element in the field of precision manufacturing, the design, manufacture and optimization of metal insert molds are of great significance in improving product quality and production efficiency. With the continuous development of the manufacturing industry and the continuous progress of technological innovation, we have reason to believe that metal insert molds will play an increasingly important role in more and more fields.

Προηγούμενος:Injection Molding: The Perfect Fusion of Craftsmanship and Functionality

Επόμενο: Injection mold: precision tool for plastic product manufacturing

-

Industrial Mold: The Backbone of Modern Manufacturing Processes

2023-5-23

Industrial mold, also known as tooling or die, is a vital component in modern manufacturing processes. It is a precision...

Δείτε λεπτομέρειες -

Revolutionizing Automotive Manufacturing with State-of-the-Art Mold Technology

2023-6-21

The automotive industry is one of the most significant sectors in the global economy, with millions of cars produced ann...

Δείτε λεπτομέρειες -

Injection mold making: Precision processes shaping the future of industry

2024-12-31

In modern manufacturing industry, injection mold manufacturing occupies a pivotal position. From plastic products in dai...

Δείτε λεπτομέρειες -

Creating a Mold for a Large Plastic Chair

2023-6-16

When it comes to manufacturing large plastic chairs, the process involves creating a mold that can be used to produce mu...

Δείτε λεπτομέρειες -

Choose the Right Medical Molded Parts Manufacturer for Your Medical Device

2023-5-7

Medical molding parts are crucial components in the healthcare industry. They are used in a wide range of applications s...

Δείτε λεπτομέρειες -

China Mold Design guide: Creating Precise and Efficient Manufacturing Solutions

2023-5-22

Mold design is a crucial part of the manufacturing process, as it involves creating a precise and efficient solution for...

Δείτε λεπτομέρειες