How can plastic injection molds efficiently produce plastic products?

Plastic injection molds are specialized tools used in plastic injection molding processes. Through special design and manufacturing processes, they can inject molten plastic into the mold cavity and, after cooling and solidifying, produce plastic products of the desired shape and size. So how do plastic injection molds efficiently produce plastic products? This article will analyze the design, manufacturing, working principle, etc. of the mold in detail.

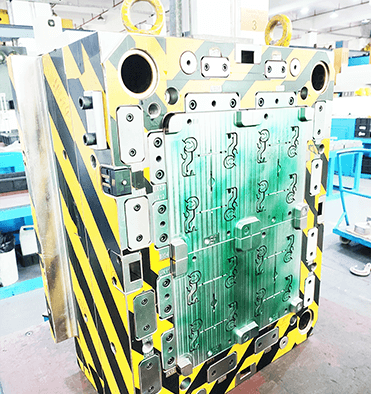

1. Plastic Injection Mold Design and Manufacturing

The design of plastic injection molds is the key to producing high-quality plastic products. Designers must determine key parameters such as mold size, parting surface, and casting system based on the structure and performance requirements of the product. The parting surface design must ensure that the plastic product can be easily removed from the mold, while the pouring system design must ensure that the molten plastic fills the mold cavity evenly and quickly.

During the manufacturing process, the mold must undergo precision machining and heat treatment to ensure its dimensional accuracy, surface quality and durability. High-precision molds can ensure the dimensional accuracy and surface quality of plastic products, while durability can extend the service life of the mold and reduce production costs.

2. Working Principle of Plastic Injection Mold

The working principle of plastic injection mold is relatively simple, but the process is very delicate. In the production process, the plastic raw material is first added to the hopper and heated to a molten state. Then, the molten plastic is injected into the casting system of the mold through the injection device. The injection device usually consists of an injection screw and an injection cylinder. The injection screw pushes the molten plastic into the injection barrel, and the injection barrel injects the plastic into the casting system.

The runner in the casting system feeds the molten plastic into the mold cavity and fills the entire cavity. After the plastic fills the cavity, the mold is cooled and the plastic cools and solidifies in the cavity. Then the mold is opened and the solidified plastic product falls out of the cavity. In order to make the plastic product fall off smoothly, an ejection mechanism such as an ejector pin and an ejector pin is usually set in the lower mold of the mold.

3. Efficient Production Characteristics of Plastic Injection Mold

High degree of automation: The injection molding process combined with the automated production line can realize large-scale automated production and improve production efficiency.

Diversity: Plastic injection mold can produce plastic products of various sizes, shapes and functions to meet various needs.

High precision: Through precise mold design and manufacturing, the dimensional accuracy and surface quality of plastic products can be ensured.

Durability: High-quality mold materials and heat treatment processes can extend mold life and reduce production costs.

4. Conclusion

In summary, plastic injection molds can efficiently produce various plastic products through precise design, manufacturing and efficient working principles. Due to their high degree of automation, versatility, high precision and durability, plastic injection molds play an irreplaceable role in the production of plastic products. At the same time, with the continuous development of technology, the performance and efficiency of plastic injection molds will continue to improve, providing more solid support for the development of the field of plastic product manufacturing.

Vorherige:Plastic Molds: Essential Tools in Industrial Manufacturing

Nächste: Plastic Moldmaking: The Innovative Force Shaping the Future of Manufacturing

-

Injection mold making: Precision processes shaping the future of industry

2024-12-31

In modern manufacturing industry, injection mold manufacturing occupies a pivotal position. From plastic products in dai...

Einzelheiten anzeigen -

Manufacturing a Plastic Middle Chair Mould: Achieving Precision and Efficiency

2023-8-30

Plastic products are widely used in various industries due to their durability, versatility, and cost-effectiveness. One...

Einzelheiten anzeigen -

Designing a High-Quality Plastic Injection Chair Mould for Ultimate Comfort

2023-7-8

Introduction: Chairs are an essential piece of furniture found in homes, offices, and various public spaces. The design ...

Einzelheiten anzeigen -

2023-4-24

Industrial molding parts are essential components used in the manufacturing and production processes of various industri...

Einzelheiten anzeigen -

Premium English Large Plastic Molds Service: Enhancing Your Manufacturing Efficiency

2023-10-26

Manufacturing companies are constantly seeking ways to improve their efficiency and productivity. One key aspect of this...

Einzelheiten anzeigen -

Erstellen großer Kunststoffformen für eine effiziente Fertigung

2023-4-14

Creating large plastic molds for efficient manufacturing is an essential part of producing high-quality plastic products...

Einzelheiten anzeigen