Household appliance plastic injection molds are widely used in the manufacturing industry to produce various components and parts for household appliances. These molds are essential for producing precise and consistent plastic parts with high efficiency.

When designing a plastic injection mold for home appliances, several factors need to be considered. First, the mold should be customized to meet the specific requirements of the appliance component to ensure the correct shape, size and functionality. In addition, the choice of mold material is critical for durability and heat resistance.

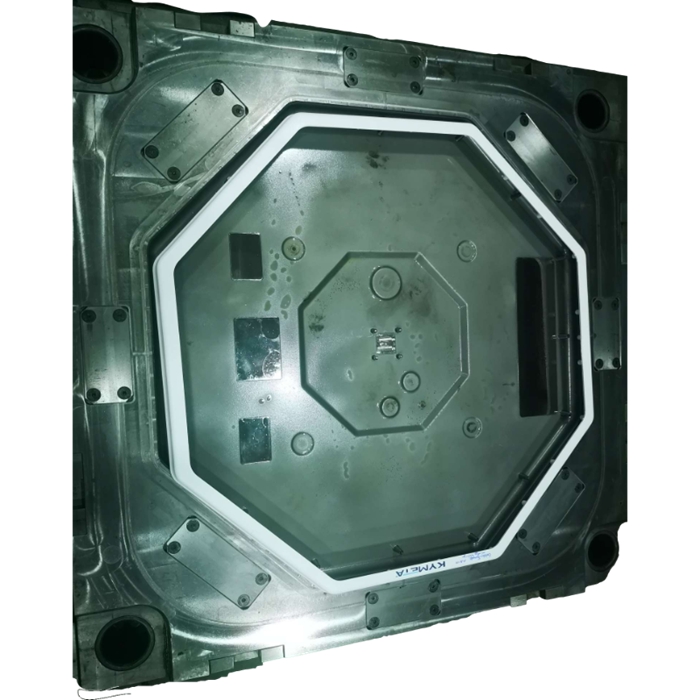

The mold design process involves creating one or more cavities that match the desired shape of the part. Molten plastic is then injected into the mold under high pressure. Once the plastic cools and solidifies, the mold is opened and the finished part is ejected.

Plastic injection molding offers many advantages for appliance manufacturing. It enables the production of complex shapes with intricate details and consistent quality. The process is highly efficient, allowing for high-volume production at a relatively low cost per unit. In addition, plastic parts produced by injection molding are lightweight, durable, and often resistant to chemicals and temperature changes.

Some common applications of plastic injection mold for home appliances include

Housings and covers: Appliances typically require protective covers or housings to ensure the safety and functionality of internal components. Injection molding can produce complex shapes with precise details and tolerances, allowing for the production of durable and robust housing and cover components.

Electrical components: Electrical components such as switches, connectors, and wiring harnesses are found in many household appliances. Injection molding can produce these components with the correct shape, size and functionality needed for safe and efficient appliance operation with high precision and consistency.

Handles and grips: Appliances often require handles or grips for easy transport and operation. Injection molding can produce handles and grips that are ergonomic, comfortable, resistant to wear and provide a secure grip.

Gaskets and seals: Household appliances often contain gaskets and seals that prevent water, moisture and other contaminants from entering the interior of the appliance. Injection molding can produce these components with high precision, ensuring an airtight and watertight seal.