How do metal insert molds play a role in manufacturing?

Metal insert molds play an important role in the manufacturing industry. They not only improve the production efficiency of products, but also ensure the stability and consistency of product quality. So how do metal insert molds play a role in the manufacturing process? The following four aspects will be discussed in detail.

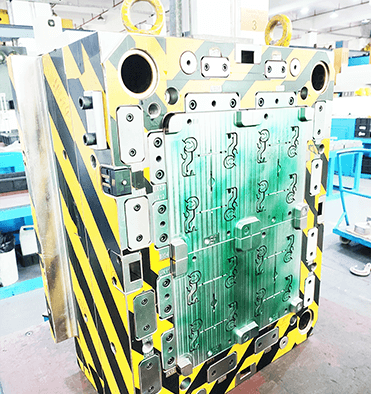

1. Metal insert mold design and construction

The design of metal insert molds is a critical link in the manufacturing process. Designers must accurately calculate the size, shape and structure of the mold according to the specific requirements and material properties of the product. The mold typically consists of several parts, including the core, cavity, gate, etc. These parts must fit closely together to ensure that the metal insert can be accurately and completely molded. At the same time, the design of the mold must also take into account the fluidity and cooling rate of the material to prevent defects during the molding process.

2. The metal insert molding process

Metal insert molds combine metal inserts with plastics or other materials through molding processes such as injection molding and die casting. During the molding process, molten metal or plastic is injected into the cavity of the mold and then solidifies under a certain pressure and temperature. The precise design and manufacture of the mold ensures that the position and shape of the metal insert remain unchanged during the molding process, ensuring the accuracy and quality of the product.

3. Wear resistance and mold life

Metal insert molds must withstand high temperature, high pressure and frequent friction during use, so the wear resistance and service life of the mold are crucial. In order to improve the wear resistance of the mold, manufacturers usually use high-quality mold steel or other special alloy materials and perform special treatments on the mold surface, such as nitriding, carburizing, and so on. These measures not only improve the hardness of the mold, but also enhance its corrosion resistance and fatigue resistance, thereby prolonging the service life of the mold.

4. Mold Maintenance and Care

Although metal insert molds have high wear resistance and long service life, regular maintenance and care are still essential. During use, the mold may fail due to wear, deformation or contamination. Therefore, manufacturers must regularly inspect and clean the mold, and repair or replace damaged parts in a timely manner. At the same time, the mold must be lubricated and rust protected to ensure that it maintains good performance and precision during long-term use.

In summary, metal insert molds play an important role in the manufacturing industry. Through precise design, accurate molding process, excellent wear resistance and service life, as well as regular maintenance and care, metal insert molds ensure efficient production and high-quality manufacturing of products.

-

Injection mold making: Precision processes shaping the future of industry

2024-12-31

In modern manufacturing industry, injection mold manufacturing occupies a pivotal position. From plastic products in dai...

View details -

Creating Large Plastic Molds: A Comprehensive Guide

2023-4-17

Creating large plastic molds can be a daunting task, but with the right tools and knowledge, it can be accomplished succ...

View details -

Aerospace Mold: Precision Tooling for High-Performance Aircraft and Spacecraft Components

2023-6-5

Aerospace mold refers to the precision tooling used in the production of high-performance aircraft and spacecraft compon...

View details -

Manufacturing High-Quality Plastic Injection Chair Moulds

2023-9-30

Introduction: Plastic injection chair moulds play a crucial role in the manufacturing process of chairs. These moulds ar...

View details -

Plastic Injection Molding: The Process and Applications

2023-5-30

Plastic injection molding is a manufacturing process that involves creating three-dimensional objects by injecting molte...

View details -

Creating Large Plastic Molds for Industrial Production

2023-4-14

Creating large plastic molds for industrial production is a complex process that involves various steps and techniques. ...

View details